SpaceX is once again pushing the limits of what’s possible in aerospace, and this time, the ambition is bigger—literally—than ever before. Elon Musk recently announced that construction on the colossal “Gigabay” is officially underway, marking the beginning of a new era in ultra–high-volume rocket manufacturing.

The statement was brief, but its implications are enormous. Gigabay is not just another building—it’s the foundation of industrial-scale Starship production. With it, SpaceX aims to build rockets faster, cheaper, and in greater numbers than at any point in history.

In this comprehensive breakdown, we explore the massive goals behind Gigabay, how SpaceX intends to achieve them, why this facility could reshape aerospace manufacturing forever, and what’s coming next for Starbase and the future Starship fleet.

What Is Gigabay and Why Does It Matter?

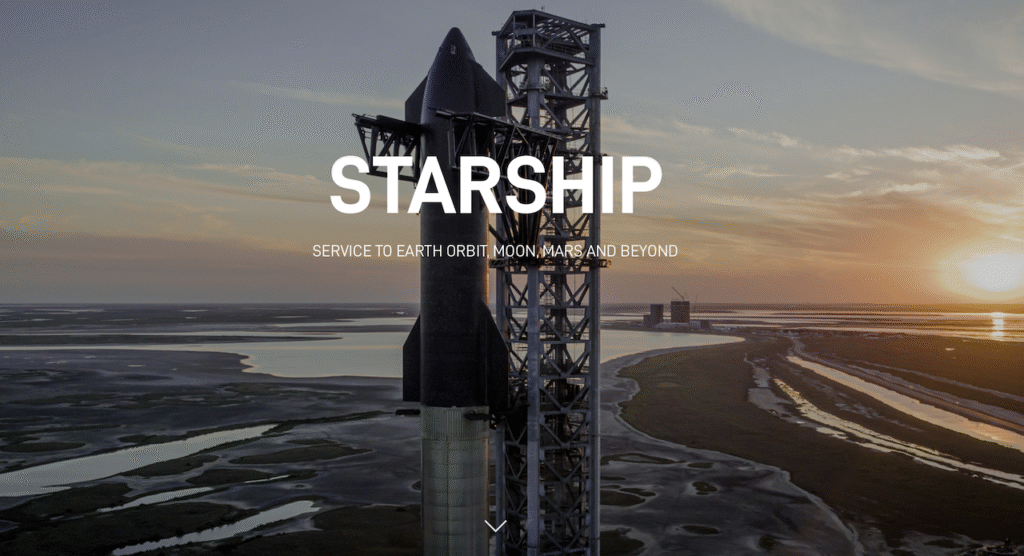

As Starship evolves through each generation—V1, V2, and now V3—every aspect of Starbase must evolve with it. Future missions to Mars, the Moon, and beyond will require not only powerful vehicles, but also a rapid and scalable production system capable of building Starships at a pace the aerospace world has never seen.

That system begins here: Gigabay.

Gigabay is SpaceX’s answer to the coming demand for ever-increasing Starship production. Musk has emphasized that building Starship prototypes by hand is unsustainable for long-term operations. SpaceX needs a factory that behaves more like an automotive assembly line—constant, efficient, and endlessly repeatable.

During a recent talk, Musk summarized this vision perfectly:

“So many spaceships will be born in the Starbase Gigabay.”

This statement isn’t an exaggeration—it’s literal. Gigabay is designed to produce thousands of Starships.

SpaceX’s Jaw-Dropping Goal: 1,000 Starships Per Year

Perhaps the most staggering part of Musk’s plan is the target output:

One Thousand Starships Per Year

Yes—you read that right. SpaceX wants Gigabay to manufacture 1,000 Starships every single year. That breaks down to:

- ~2–3 Starships per day

- 10–15 vehicles being assembled simultaneously

- A production cadence never before attempted in aerospace

Musk even admitted:

“It hasn’t been built yet, but we’re building it. This will be one of the biggest structures in the world.”

And he means biggest.

Gigabay’s Unprecedented Size and Structure

Gigabay’s scale alone tells the story:

- 700,000 sq ft of floor space

- Over 65,000 square meters

- 380 feet (116 meters) tall—enough height to fully assemble Super Heavy and Starship under one roof

- Capacity to work on 10–15 prototypes at once

This is more than just a factory—it’s the world’s first rocket megafacility.

The size is necessary to achieve Musk’s production targets. Traditional rocket factories often produce a few vehicles per year. Gigabay aims for several per day. That level of output requires no less than a monumental structure filled with advanced automation, robotics, high-speed welding systems, and overhead cranes spanning multiple levels.

SpaceX is not just scaling up production—they’re redefining it.

Why SpaceX Needs So Many Starships

To many, building thousands of rockets a year sounds absurd. But when you examine the future mission architecture for Mars, it becomes clear that this production rate is not just ambitious—it’s necessary.

Mars Launch Windows and High-Cadence Missions

Mars launch opportunities occur in windows. During these periods, SpaceX plans to send:

- Cargo Starships

- Crew vehicles

- Tanker Starships

- Support craft

In order to support even one deep-space mission, the Starship architecture requires 10 or more tanker flights to refill the primary spacecraft in orbit.

Musk has stated that many tankers will not return—they’re expendable. So SpaceX must maintain a constant supply.

Reusability Doesn’t Eliminate Production Needs

Even with reusability, a Mars campaign may require:

- Hundreds of tankers

- Dozens of cargo ships

- Multiple crew vehicles

All available at the same time. Mass production is the only way.

And that’s where Gigabay comes in.

A Second Gigabay? SpaceX’s Florida Expansion

Gigabay Texas is only one piece of the puzzle. SpaceX also plans a second Gigabay in Florida, designed to match or exceed the output of the Texas facility.

Together, the two sites could produce:

Up to 2,000 Starships Per Year

That’s four to six Starships every day.

This level of production is unprecedented. For comparison:

- The NASA Space Launch System (SLS) has taken nearly a decade and tens of billions of dollars just to produce one vehicle.

- Traditional rockets often require years of precision manufacturing.

SpaceX is flipping that model on its head.

Gigabay’s Ultra-Low Cost: $250 Million

Even more shocking is the cost. Gigabay is expected to cost around $250 million.

For perspective, that’s approximately:

- The price of four Falcon 9 launches

- A fraction of the cost of traditional government-built aerospace facilities

This price point highlights SpaceX’s obsession with lean, efficient, rapid construction. By the time others build a single, expensive facility, SpaceX could build multiple Gigabays.

Why Modular, Expandable Design Matters

One concern often raised is the need for long-term flexibility.

SpaceX evolves fast. Buildings that aren’t built for modification often get demolished and replaced—a costly and time-consuming process.

The ideal Gigabay must be:

- Expandable

- Modular

- Reconfigurable

This allows Gigabay to grow as Starship evolves.

Many observers believe modularity will be just as important as raw output.

Construction Progress: Gigabay Takes Shape

SpaceX has already made rapid progress:

- Four major steel frame piles have been completed

- Cranes are in place

- The facility’s outline is now visible

- Major frame sections will rise next

- Roofing and wall panels will follow

- Then come internal structures, walkways, and office areas

Given SpaceX’s construction track record, speed may accelerate dramatically.

Less Than One Year to Completion?

Megabay 2—another massive Starbase structure—was built in under three months.

Even though Gigabay is larger and more complex, analysts expect its construction timeline to fall under one year.

If this pace holds, Gigabay could be operational by the third quarter of next year.

At that moment, the world will witness the birth of the most aggressive rocket production facility ever attempted.

Starfactory: The Backbone of Starship Production

Gigabay is only one piece of the high-volume production chain. To keep up with its demands, SpaceX must also expand the Starfactory, where Starship components are fabricated.

Recent progress includes:

- Completed exterior structure

- Internal upgrades for production flow

- Surging numbers of rings, nose cones, domes, and flaps

- Evidence of accelerated manufacturing efficiency

But this is just the beginning.

To support 1,000 Starships per year:

Starfactory Must Match Gigabay’s Output

Every Starship requires:

- Stainless-steel rings

- Domes

- Thrust structures

- Flaps

- Nose cones

- Plumbing

- Wiring

- Thermal protection systems

These components must arrive at Gigabay in a nonstop, uninterrupted stream.

Otherwise, the massive stacking bays will sit idle.

Automotive-Style Production Comes to Aerospace

Musk’s vision for Starfactory is inspired by automotive manufacturing:

A Linear Flow Production Line

Each workstation performs a single specialized task:

- Welding

- Plumbing installation

- TPS tile application

- Insulation

- Structural checks

- Quality verification

The advantage?

- No idle time

- No delays waiting on other teams

- Easy error isolation

- Continuous workflow

This philosophy has never been applied at scale in aerospace—until now.

The Arrival of Starship V3 and the Need for Speed

SpaceX is now transitioning to Starship V3, designed for:

- High-value missions

- Reliable landing

- Orbital refilling

- Efficient reuse

Mars missions depend heavily on orbital refilling, making tanker production urgently necessary.

To keep up with Starship Version 3 development, both Megabay 1 and Megabay 2 must accelerate their stacking cadence.

And even once Gigabay is operational, they will remain critical to the overall production flow.

Florida Needs a Starfactory Too

SpaceX plans a second Gigabay in Florida, but so far there is no official plan for a Starfactory 2.

Without it, moving components between Texas and Florida would be inefficient.

For true manufacturing independence, Florida must have:

- Gigabay Florida

- Starfactory 2

Ideally both under construction by 2026, allowing full production speed by 2027.

Starbase Becomes the First Rocket Manufacturing City

The big picture is clear:

SpaceX is shifting from experimental development to industrial-scale production.

Starbase is rapidly becoming:

- The world’s first rocket manufacturing metropolis

- A high-volume assembly hub

- A launch site

- A testing complex

- A research and development center

It will be louder, busier, and more dynamic than ever before.

The transition from handcrafted prototypes to mass-produced interplanetary vehicles has already begun.

Are We Ready for the Next Evolution of Starbase?

Gigabay is more than a building—it is the cornerstone of humanity’s next major leap into space.

- Thousands of Starships

- Mars colonization

- Lunar bases

- Massive cargo deployment

- Global point-to-point travel

- A fully reusable, low-cost rocket fleet

All of this depends on Gigabay’s success.

SpaceX is on the brink of creating the most advanced, most efficient, and most ambitious rocket production system in history.

Are you ready to witness the beginning of the craziest rocket manufacturing era ever?

If you are—type GIGA in all caps in the comments!

FAQs

1. What is SpaceX Gigabay?

Gigabay is SpaceX’s massive new rocket manufacturing facility designed to produce Starships at an unprecedented scale—up to 1,000 per year.

2. Why is Gigabay important for SpaceX?

Gigabay enables industrial-scale Starship production, which is essential for Mars missions, lunar operations, and high-frequency orbital launches.

3. How many Starships will Gigabay produce annually?

SpaceX aims to produce 1,000 Starships per year, or roughly 2–3 Starships per day once fully operational.

4. How big is Gigabay?

Gigabay covers approximately 700,000 square feet and rises 380 feet tall, large enough to assemble full Starships indoors.

5. When will Gigabay be operational?

Based on current construction speed, Gigabay could be operational by the third quarter of next year.

6. Why does SpaceX need so many Starships?

Future Mars missions, orbital refueling, large-scale cargo transport, and rapid reusability all require a massive fleet of Starships.

7. Will Gigabay reduce Starship costs?

Yes. Mass production, automation, and efficient workflow will significantly reduce the cost of building each Starship.

8. How much does Gigabay cost to build?

Gigabay is expected to cost around $250 million, which is extremely low compared to traditional aerospace facilities.

9. What technologies will Gigabay use?

Gigabay will employ automated welding, robotic assembly systems, high-capacity cranes, and modular production workflows.

10. Will SpaceX build another Gigabay?

Yes. SpaceX plans a second Gigabay in Florida, eventually allowing combined annual output of up to 2,000 Starships.

11. What role does Starfactory play in production?

Starfactory manufactures the components—rings, domes, flaps, and nose cones—that Gigabay will assemble into complete Starships.

12. How does this differ from traditional rocket manufacturing?

Traditional rockets take years to build. Gigabay introduces an automotive-style assembly line, allowing rocket production on a daily basis.

13. Why does Starship need so many tanker flights?

Deep-space missions require orbital refueling, which may need 10 or more tanker flights for a single mission.

14. Will Gigabay support the Starship V3 program?

Yes. Gigabay is designed to mass-produce the V3 generation, capable of reliable landing, refueling, and reuse.

15. How many Starships might SpaceX need for Mars colonization?

Potentially hundreds to thousands, depending on cargo needs, crew transport, and long-term settlement planning.

16. Is Gigabay part of SpaceX’s long-term vision?

Absolutely. Gigabay represents the shift from prototype development to full-scale interplanetary vehicle manufacturing, a key step toward making humanity multiplanetary.

Read More:

- Tesla CEO Elon Musk teases insane capabilities of next major FSD update

- Tesla Full Self-Driving lands in a new country, its 7th

- $6,789 Tesla Flying Car FINALLY HIT The Market! What’s Inside in First Look?

- The Tesla Semi 2026 Update is HERE

- BAD NEWS! First SpaceX Starship Booster V3 Exploded During Test! Here’s What Exactly Happened

A Henry Ford for rockets.

Why do You run ads on selling Tesla Motorhomes and Pi phones when they is not anywhere to be Purchased what a Standing Joke you are.

I Will never buy anything From Tesla Ever!!!!

What a Internet joke its laughable what a waste of everyone’s time get a life!!!!!!

Your All Losers get a real job!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

LOL>>>>>>>>>>>>>>>>>>>