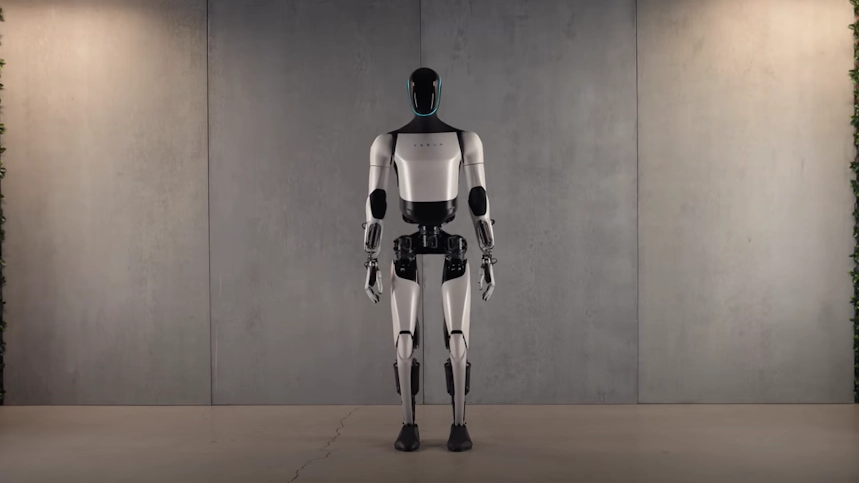

Tesla’s Optimus humanoid robot has become one of the most discussed and controversial tech projects of the decade. With Elon Musk repeatedly promising a robot that could someday be mass-produced like a car, the big question remains:

How much will the Tesla Optimus robot cost when it finally goes on sale?

In this article, we’ll break down everything we know about Tesla’s ambitious Gen 3 Optimus production plan, the $1,000 cost claim, the Fremont factory transformation, and what Gen 3 is expected to deliver when it hits the market.

Why Tesla’s Optimus Price Claim Sounds Too Good to Be True

Elon Musk has repeatedly stated that Tesla can produce Optimus at a cost as low as $1,000 per unit. He also hinted at a commercial launch by 2026, which would make Optimus one of the most affordable humanoid robots ever.

But there’s one big truth you can’t ignore:

Elon Musk has never been great at keeping promises about product pricing.

The $10,000–$20,000 price range that Musk mentioned years ago sounded optimistic, but it was at least plausible. The $1,000 claim, however, is almost hard to believe—unless Tesla can truly master mass manufacturing at unprecedented scale.

The Biggest Challenge: Mass Manufacturing a Humanoid Robot

Tesla isn’t just building a robot. They’re building a robot factory.

To avoid the Optimus costing hundreds of thousands of dollars, Tesla needs scale production, automation, and a manufacturing strategy that resembles car production more than traditional robotics assembly.

That’s why the Fremont factory transformation matters so much.

The Fremont Factory Transition: Why It Matters

Tesla is preparing to wind down production of Model S and Model X, and repurpose part of the Fremont factory to build Optimus Gen 3.

This isn’t a shutdown of vehicle manufacturing — it’s a strategic shift:

- Model S and Model X are low-volume compared to Model 3 and Model Y

- Model 3 and Model Y production remains unchanged

- Space freed by Model S and X will be used for Optimus Gen 3 production

Tesla aims for a staggering 1 million units per year at Fremont, and Gen 4 production in Texas is expected to ramp up even higher.

This announcement caused major waves across both the automotive and robotics industries, and for good reason.

What Does the Gen 3 Production Line Look Like?

Tesla has not shared full public details yet, but based on their factory approach, we can predict how the production line will operate:

1. Island-style assembly

Instead of long conveyor belts like a car factory, early Optimus production will rely on island-style stations where:

- Legs, torso, arms, and head are assembled separately

- Cable routing and enclosure sealing are completed

- Intermediate quality checks are performed at each step

2. Rigorous End-of-Line Testing

A humanoid robot cannot simply be “powered on” to pass final testing.

To pass final inspection, Optimus must complete:

- Joint zeroing and calibration

- Sensor validation

- Controlled walking and balance tests

- Object manipulation

- Emergency stop verification

- Thermal and acoustic testing

Some units may undergo extended burn-in before shipment.

Gen 3 vs Gen 2.5: What’s Changing?

Tesla has already gone through three major design revisions, and Optimus’ hands have been redesigned four times in two years.

Gen 2.5 is not a true “generation” — it was more of a refinement phase. But it marked a major step toward commercialization.

Optimus Gen 2.5: The Baseline

Gen 2.5 established the basic shape and functionality:

- Height: ~5’10”

- Weight: ~138 lbs

- Five-fingered hands

- Walking speed: ~1.3 mph

- Strong emphasis on stability and safety

- Exterior design moved from industrial to consumer-ready

But Gen 2.5 was never meant to be final.

Optimus Gen 3: The Real Commercial Product

Gen 3 is expected to push the design much further, while still keeping the human-centric form factor.

Key Gen 3 Improvements Expected

1. Better Materials

Gen 3 is expected to reduce metal usage and introduce:

- Carbon fiber composites

- High-grade polycarbonate

- Lighter and stronger structural components

Reducing weight is crucial because:

- It improves battery life

- Enhances balance and agility

- Reduces wear and tear

2. Improved Wiring & Sealing

Expect:

- Internal wiring

- Better joint sealing around wrists and ankles

- Enhanced durability for industrial environments

3. Human-Robot Interaction

Gen 3 may introduce a visual display or LED interface in the head to communicate:

- Battery level

- Task progress

- Connectivity status

This will make Optimus feel more “alive” and approachable.

4. Full Voice Communication

This is perhaps the biggest leap.

Gen 3 is expected to support:

- Custom voices

- Personalized personalities

- Natural conversational behavior

Optimus will not only respond to commands — it will learn preferences and adapt over time.

Gen 3 Hardware: A Major Leap

1. Next-Generation Drivetrain

Expect smoother and faster motion with:

- Improved range of motion

- Better stability

- Greater strength for lifting and bending

2. Bigger Battery

Early prototypes had a 2.3 kWh battery with 6–8 hours of operation.

Gen 3 could increase this to ~3 kWh, pushing battery life toward 12 hours.

Tesla will likely balance battery weight by distributing mass in the lower body.

3. Powerful AI Hardware

Tesla is expected to use AI5, their next-generation AI hardware platform, offering:

- Up to 10x performance

- Peak power consumption around 700–800W

- Efficient idle power consumption (~100W)

This enables real-time learning and advanced task execution.

The Hands: The Real Game-Changer

Optimus Gen 3 is expected to feature hands with up to 22 degrees of freedom, doubling the dexterity of Gen 2.5.

Even with 11 degrees of freedom, Gen 2.5 already proved it could:

- Handle delicate objects like eggs

- Manipulate battery cells

- Perform basic human-level tasks

With 22 DOF, Gen 3 could potentially:

- Thread a needle

- Play instruments

- Perform complex assembly

- Water plants

No other humanoid robotics manufacturer has publicly committed to this level of dexterity at scale.

How Optimus Learns: From Video and Humans

Tesla has emphasized that Optimus is not a rigidly programmed robot. Instead, it’s a learning system.

Optimus can learn tasks by:

- Watching humans perform tasks

- Watching videos

- Receiving verbal instructions

This dramatically reduces training time and cost.

Of course, safety is a concern. Tesla claims the robot will:

- Recognize dangerous actions

- Assess risks

- Enforce strict software constraints

This is where Tesla’s experience with autonomous driving becomes crucial.

Why Fremont Is the Right Place for Optimus

Tesla chose Fremont because:

- It has the most mature manufacturing ecosystem

- Experienced labor force

- Strong automation infrastructure

- Rapid iteration culture

The city government even emphasized Fremont’s ability to support complex large-scale manufacturing.

Importantly, Tesla has stated this shift will not cause layoffs, and may even increase headcount.

When Will You Be Able to Buy an Optimus Robot?

The timeline is not a single event—it’s a series of milestones:

2026

- Production intent reveal expected

- Formal production targeted before the end of 2026

2027

- Broader availability expected

- Early deployment likely limited

Tesla’s timeline depends on:

- Manufacturing ramp

- Software maturity

- Safety validation

- Real-world testing

The $1,000 Price Claim: Realistic or Not?

Tesla’s claim of $1,000 per unit is ambitious, to say the least.

Even if the robot becomes commercially available, early units will likely cost far more due to:

- Research and development

- Low-volume production

- Safety validation

- Supply chain constraints

But Tesla’s strategy is clear:

Build the factory first, then scale to reduce costs.

If Tesla can achieve the scale of 1 million units per year, the cost per unit could theoretically fall dramatically—possibly approaching Musk’s optimistic pricing predictions.

Final Thoughts: Optimus Gen 3 Could Change Everything

Tesla’s Optimus robot is more than a product—it’s a bet on the future of manufacturing, AI, and human labor.

If Tesla succeeds, Optimus could:

- Revolutionize domestic life

- Transform industrial labor

- Create a new category of consumer robots

But the biggest challenge remains: Can Tesla truly mass produce humanoid robots at scale?

Only time will tell. But one thing is clear:

Tesla is serious about Optimus. And the next few years will reveal whether this bold gamble pays off.

FAQs

1. When will the Tesla Optimus robot go on sale?

Tesla has indicated commercial availability around 2026, but broader availability is more likely in 2027 after production ramps up.

2. How much will the Optimus robot cost?

Elon Musk has claimed Tesla could produce Optimus at around $1,000, but early units will likely cost significantly more due to development and low initial production volumes.

3. Will Tesla really produce 1 million Optimus robots per year?

Tesla has announced plans for a 1 million units per year production capacity at Fremont, with even higher volumes expected in Texas for future generations.

4. Why is Tesla using Fremont for Optimus production?

Fremont offers:

- Experienced labor

- Mature automation systems

- A dense manufacturing ecosystem

- Faster iteration and testing cycles

5. Will Tesla stop producing cars at Fremont?

No. Tesla will continue producing other models. Only the Model S and Model X space will be repurposed for Optimus production.

6. What is Optimus Gen 3?

Optimus Gen 3 is the next major iteration of Tesla’s humanoid robot, designed for mass production and real-world deployment.

7. What improvements will Gen 3 have over Gen 2.5?

Gen 3 is expected to feature:

- Better materials

- Improved design

- Full voice communication

- Enhanced mobility

- More advanced hands (up to 22 DOF)

8. What is the height and weight of Optimus?

Gen 2.5 was about 5’10” and 138 lbs. Gen 3 is expected to maintain similar human proportions.

9. Will Optimus have a voice?

Yes. Tesla has confirmed Optimus will support custom voices and personalities, powered by advanced AI.

10. How long will Optimus run on a battery?

Early prototypes ran 6–8 hours. Gen 3 could potentially reach up to 12 hours with improved battery technology.

11. What will Optimus be able to do?

Tesla expects Optimus to perform:

- Household tasks

- Industrial assembly

- Human interaction

- Learning from videos and human demonstrations

12. Will Optimus be safe to use at home?

Tesla claims Optimus will have strict software safety constraints, risk assessment, and hazard recognition to prevent dangerous actions.

13. What kind of AI will Optimus use?

Optimus is expected to use Tesla’s next-gen AI hardware (AI5) and large language models for communication and learning.

14. What is the main challenge in mass-producing humanoid robots?

Humanoid robots require extreme precision in:

- Joint geometry

- Actuator placement

- Sensor alignment

- Cable routing

Even small changes can cause major issues.

15. What does the production line look like?

Early production will likely use island-style assembly stations, not long conveyor belts, to ensure quality and precision.

16. Will Tesla lay off employees during the transition?

Tesla has stated that no layoffs are expected and headcount may even increase.

17. What does “production intent reveal” mean?

It refers to Tesla showcasing the final production version of Gen 3, indicating the design is ready for mass manufacturing.

18. What makes Tesla’s Optimus different from other humanoid robots?

Tesla’s advantage is:

- Mass manufacturing experience

- Advanced AI integration

- Potentially massive scale production

- Unique focus on human-like form factor

19. What happens after Gen 3?

Tesla is already researching Gen 4 and Gen 5, which will continue improving performance, design, and production scale.

Read More:

- Breaking: Samsung Users Will Get Free Internet After a Deal with SpaceX

- Tesla Semi lines up for $165M in California incentives ahead of mass production

- Tesla exec: Preparations underway but no firm timeline yet for FSD rollout in China

- Lemonade launches Tesla FSD insurance program in Oregon

- Tesla executive moves on after 13 years: ‘It has been a privilege to serve’

- Tesla Semi pricing revealed after company uncovers trim levels