The conversation about electric cars often begins with range and ends with price. But for everyday drivers, the real friction lies elsewhere. It’s the fear of a battery fire after a crash, the ever-increasing insurance bill, the minutes lost at a charger, and the uneasy question of where a worn-out battery pack will go.

Tesla’s new aluminum-ion battery steps into this space, offering promises that touch safety, time, money, and sustainability. But how exactly could this breakthrough change the EV landscape?

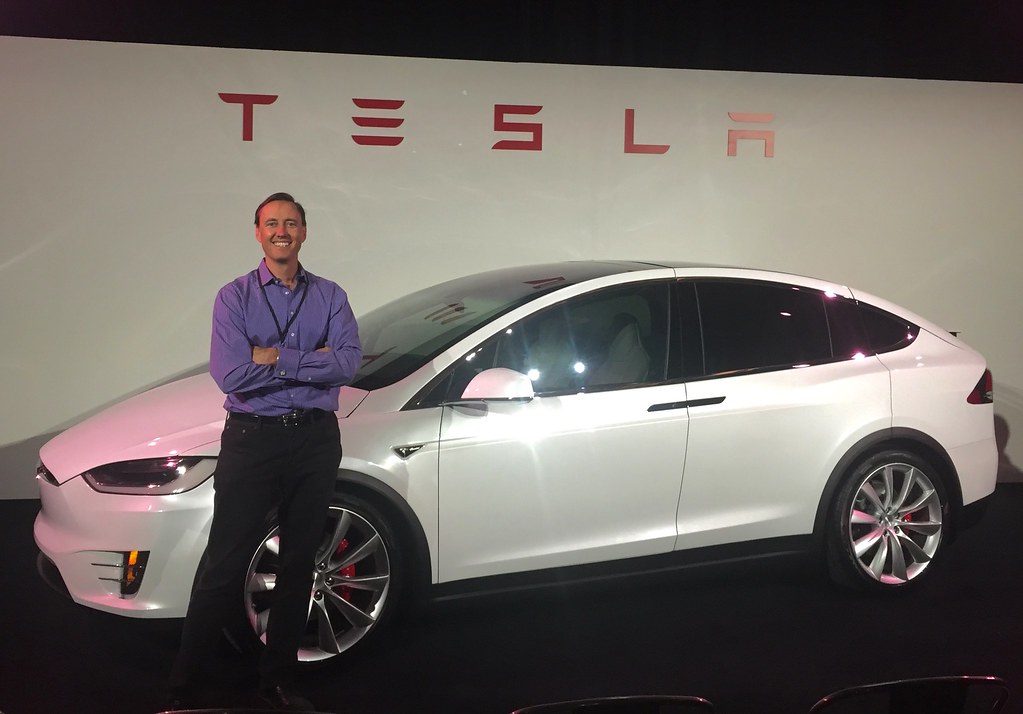

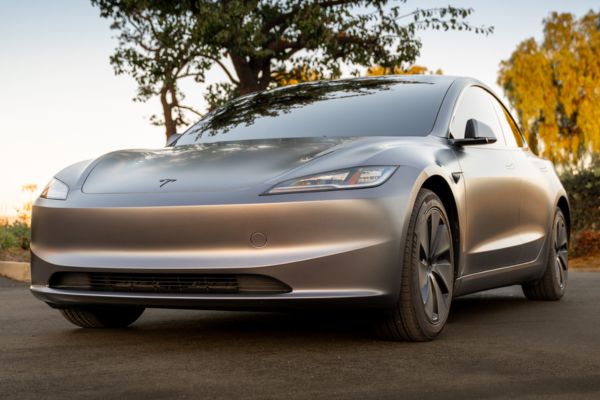

In this article, we dive deep into Tesla’s aluminum-ion battery for the 2026 Model 2, exploring its potential to improve crash safety, speed up charging, lower ownership costs, and integrate with global recycling networks.

How Is Tesla’s Aluminum-Ion Battery the Hidden Fix to Fires and Insurance Nightmares?

Recent leaks from Tesla’s pilot facilities in Fremont and Giga Texas suggest that the aluminum-ion cells for the 2026 Model 2 are already in low-volume production. Tesla insiders report that these packs have been tested in over 200 pre-production vehicles since late 2024, undergoing crash simulations and endurance cycles far above industry standards.

Why Make the Switch from Lithium-Ion?

The fire problem with lithium-ion batteries is impossible to ignore. Once compromised, a lithium cell can reach temperatures above 500° C in under 90 seconds—hot enough to ignite cabin materials or melt chassis components. Laptops, phones, and entire EV fleets have faced recalls or bans due to spontaneous fires, leaving insurance companies cautious. Many drivers pay $400–$600 extra annually to offset this fire risk.

Tesla’s aluminum-ion battery addresses this head-on:

- Leaked crash test data shows that even when aluminum-ion cells are punctured with forces exceeding 3,000 newtons, internal temperatures never exceeded 120° C, far below lithium’s 500° C threshold.

- Instead of a thermal runaway, aluminum-ion cells dissipate energy safely without generating flames.

- Simulations show a 75 kWh aluminum-ion pack releases less than 5 kWh of heat energy externally, compared to over 40 kWh for lithium-ion packs.

The implications are enormous. Independent studies predict up to 80% fewer fire-related accidents for vehicles with aluminum-ion packs. Insurance modeling indicates annual premiums could drop by $300–$500, translating to $3,000–$5,000 savings over a decade.

This is a game-changer for older buyers calculating lifetime costs. The question shifts from “Will it catch fire?” to “Why stick with lithium at all?”

How Could Tesla’s Aluminum-Ion Battery Deliver Truly Fast Charging Without Sacrificing Longevity?

Range anxiety isn’t just about battery capacity—it’s also about charging speed and the ability to handle repeated fast charging.

Leaked internal tests show prototype aluminum-ion packs of 55–60 kWh maintain high current acceptance across a wider state of charge than lithium batteries. This translates to:

- Flatter charging curves, with less power drop-off after 50–60% capacity.

- Reduced heat generation and slower internal resistance growth, allowing repeated high-power sessions without extreme thermal management.

- 10–80% charging in just over a dozen minutes under moderate conditions.

Consistency Matters

Drivers care more about daily reliability than peak performance. Aluminum-ion batteries:

- Reduce seasonal variations in charging times.

- Maintain durability over 1,000+ fast-charging cycles.

- Operate cooler, enabling smaller thermal systems, fewer fans, and reduced auxiliary energy consumption.

Rather than simply increasing kilowatt hours, Tesla’s aluminum-ion packs focus on cutting waste, heat, and complexity, turning a small EV into a credible weekend traveler without the typical drawbacks of lithium-based systems.

Why Might Tesla’s Aluminum-Ion Battery Reshape Cost Structures, Supply Chains, and Home Energy Economics?

Lifetime ownership costs go beyond sticker price and electricity. They depend on:

- Stable material costs

- Reliable supply chains

- Battery utility while parked

Tesla’s aluminum-ion battery addresses all three.

Material Advantages

- Aluminum is abundant and globally recycled, offering price stability compared to lithium.

- Aluminum-based current collectors reduce copper mass, shaving kilograms and lowering assembly costs.

Production Benefits

- Cooler operation allows smaller thermal systems, fewer valves, and simplified cooling loops.

- Tesla’s structural battery integration reduces component counts and cycle times, improving margins.

Energy and Grid Potential

- Aluminum-ion packs tolerate repeated cycling, making vehicle-to-home (V2H) and vehicle-to-grid (V2G) use practical.

- A 10 kWh nightly transfer could save $320–$580 per year on electricity bills.

- During outages, a 56–60 kWh pack could power essential loads for 1–2.5 days, depending on usage.

Signals to Watch

Investors should track:

- New aluminum electrode and current collector lines.

- Simplified thermal system schematics.

- Relaxed fast-charging warranties.

These indicators would confirm that Tesla’s aluminum-ion battery is truly bending the cost curve for mass-market EVs.

How Can Tesla’s Aluminum-Ion Battery Turn Today’s Waste Into Tomorrow’s Raw Material?

Tesla isn’t just innovating for performance—they’re also tackling battery recycling.

The Lithium Recycling Problem

- Recycling 1 ton of lithium EV batteries costs $4,000–$6,000, while recovered lithium carbonate sells for under $3,000.

- More than 70% of spent lithium packs are warehoused or landfilled.

- By 2030, the US could generate 1.2 million tons of lithium battery waste annually—equivalent to 40,000 shipping containers.

Aluminum’s Advantage

- Global aluminum recycling handles 20+ million tons annually.

- Aluminum retains nearly 100% of its properties after recycling.

- Tesla could feed retired Model 2 packs into existing smelters, turning old batteries into new materials.

Economic and Environmental Impact

- Recycling aluminum-ion packs may cost under $1,200 per ton, with 95% recovery rates.

- Buyers in 2026 could see their battery materials still circulating in 2050, reducing landfill waste and toxic liabilities.

Tesla’s aluminum-ion strategy promises sustainability, affordability, and a closed-loop system for EV batteries—a first for mass-market electric vehicles.

Conclusion: Is Tesla’s Aluminum-Ion Battery a Game-Changer?

Tesla’s aluminum-ion battery promises:

- Lower fire risk and safer crash outcomes

- Faster, more consistent charging

- Steadier insurance costs

- A recycling path that already exists

If these benefits scale as projected, the Model 2 transforms from a compromise EV into a smarter way to own, power, and eventually reuse.

The big question remains: would you trust Tesla’s aluminum-ion battery and support wider adoption if the data matches the promise?

For those following Tesla’s evolution, these developments could mark a historic shift in EV ownership, cost management, and environmental responsibility.

FAQs

1. What is Tesla’s aluminum-ion battery?

Tesla’s aluminum-ion battery is a next-generation EV battery technology that uses aluminum as the primary material for the cathode instead of lithium, promising faster charging, improved safety, and lower costs.

2. When will Tesla’s aluminum-ion battery debut?

Leaks suggest it could debut with the 2026 Tesla Model 2, currently in low-volume production for testing and pilot vehicles.

3. How is aluminum-ion safer than lithium-ion?

Aluminum-ion cells generate far less heat during damage, reducing the risk of fires in crashes by up to 80% compared to lithium-ion batteries.

4. Will insurance premiums decrease with aluminum-ion batteries?

Yes. Reduced fire risk may lower insurance premiums by $300–$500 annually for vehicles like the Model 2.

5. Can aluminum-ion batteries charge faster than lithium-ion?

Yes. Prototype packs maintain high current acceptance across a wider state-of-charge, allowing 10–80% charging in just over a dozen minutes under moderate conditions.

6. Do aluminum-ion batteries degrade slower?

Aluminum-ion packs experience gentler capacity fade and slower internal resistance growth after repeated fast charging, increasing longevity compared to lithium-ion batteries.

7. How much does an aluminum-ion battery weigh?

Using aluminum reduces copper content and structural mass, potentially shaving dozens of kilograms off the total pack weight.

8. Are aluminum-ion batteries more cost-effective?

Yes. Aluminum is abundant and cheaper than lithium, and recycling aluminum costs less, potentially lowering lifetime ownership costs.

9. Can aluminum-ion batteries be recycled?

Absolutely. Aluminum is almost 100% recyclable, and Tesla is reportedly planning to integrate retired packs into existing aluminum recycling infrastructure.

10. How does Tesla’s aluminum-ion battery affect thermal management?

It runs cooler under load, allowing simpler, smaller cooling systems, reducing energy consumption, and minimizing failure points.

11. Will aluminum-ion batteries support vehicle-to-grid (V2G) applications?

Yes. Lower heat generation and tolerance for repeated cycling make them suitable for V2G or vehicle-to-home energy usage.

12. How long will an aluminum-ion battery last in daily use?

Early tests suggest consistent performance over thousands of cycles, potentially supporting 8+ years of typical daily driving without significant degradation.

13. Is aluminum-ion technology proven at scale?

Not yet. Tesla has tested over 200 pre-production vehicles, but large-scale deployment will take time to confirm real-world performance.

14. Can aluminum-ion batteries withstand crashes?

Yes. Laboratory simulations show punctured aluminum-ion cells reach only about 120°C, far below the thermal runaway threshold of lithium-ion cells.

15. How much energy is lost in a damaged aluminum-ion battery?

A fully damaged 75 kWh aluminum-ion pack releases less than 5 kWh externally, compared to over 40 kWh for an equivalent lithium-ion pack.

16. Will Tesla still use lithium in other vehicles?

Yes. Lithium-ion batteries will remain in production for other models, while aluminum-ion is focused on the Model 2 and future mass-market EVs.

17. How does aluminum-ion impact charging infrastructure?

Faster, more consistent charging reduces dwell times at stations, allowing more vehicles to be served without building additional stalls.

18. Does aluminum-ion affect resale value?

Potentially. Lower fire risk, consistent performance, and recyclable materials could improve resale value compared to lithium-ion EVs.

19. Can aluminum-ion batteries operate in extreme temperatures?

Yes. Reduced heat buildup and slower resistance growth allow better performance in both winter and summer conditions.

20. Why is Tesla focusing on aluminum instead of lithium?

Aluminum is abundant, cheaper, safer, easier to recycle, and offers faster charging with lower thermal risk, aligning with Tesla’s goal for mass-market EV adoption.

Read More:

- Elon Musk Declared Starship V3 Facing ‘Big Problem’ with New-Gen Raptor

- xAI’s Grokipedia goes live, gets praise from Wikipedia co-founder

- Tesla prepares for full-throttle manufacturing of major product

- The truth about Tesla ‘Mad Max’ mode from an actual user

- Tesla board chair reiterates widely unmentioned point of Musk comp plan

- Elon Musk’s Tesla Pi Pad Just Revealed! TRUTHS 7 SHOCKING Features You Need To Know HERE