Tesla’s latest milestone has the electric vehicle world buzzing: the Tesla Semi has been tested charging at 1.2 megawatts (MW)—a level that seems almost unreal to most Americans. While megawatt charging is already routine in China, especially for passenger EVs, it’s a huge technological leap in the U.S., where charging infrastructure is still catching up.

But beyond the excitement lies a complex reality: can 1.2 MW charging truly scale for long-haul trucking in the U.S.? And how did Tesla solve the major technical challenges that previously held the Semi back?

Let’s break down the facts, the engineering, and what it means for the future of electric trucking.

Why 1.2 MW Charging is a Game-Changer

For most Americans, the fastest charging we see is around 250 kW to 350 kW. That’s fast—until you compare it to 1.2 MW, which is 4 to 5 times higher than even the most powerful consumer chargers.

When Tesla released a video showing the Semi pulling 1,200 kW from a mega charger, the internet erupted. Many saw it as another Elon Musk breakthrough—proof that Tesla is pushing EVs into new territory.

But the real story is more complex.

Why 1.2 MW is Not Just About Power

Charging at 1.2 MW isn’t just about pushing energy into a battery faster. It’s about solving a system-level challenge:

- Grid coordination

- Thermal management

- Power electronics

- Safety systems

- Industrial-grade reliability

In the U.S., high-power charging is fragmented and limited by local grid constraints. To deliver 1.2 MW repeatedly and reliably across American freight routes is a major engineering accomplishment.

Megawatt Charging Isn’t New—But Tesla Made It Practical

China has already pushed megawatt charging forward, even for passenger EVs. But the key difference is infrastructure.

The Real Difference is the Charging System

In the U.S., high-power charging stations are rare, and the grid often can’t support large power demands. A single Tesla Semi charging at 1.2 MW consumes as much power as a small neighborhood.

That’s why Tesla’s 1.2 MW test matters—it proves the system can handle it, not just the vehicle.

Tesla Semi’s Battery Needs a Massive Power Input

The Tesla Semi isn’t just a bigger Model 3. It’s a Class 8 truck, with an estimated battery capacity of 800–900 kWh—about 10 times larger than a typical electric sedan battery.

Tesla previously claimed the Semi could recharge 70% in 30 minutes, which many experts doubted. The math is brutal:

To charge 600 kWh in 30 minutes, you need sustained power above 1 MW.

That’s why the 1.2 MW test changes everything. It proves Tesla is actively validating megawatt charging in real-world conditions.

What Makes the Tesla Semi Viable for Fleets?

Fleet operators care about:

- Repeatability

- Uptime

- Total cost of ownership

- Reliability

Tesla already has major early customers like PepsiCo, reporting real-world ranges approaching 500 miles. That suggests Tesla has solved major issues such as:

- Battery durability

- Thermal stability

- Drivetrain efficiency

However, charging power is only part of the story.

The Major Challenges of 1.2 MW Charging

1) Heat Management

At megawatt levels, even small electrical resistance creates enormous heat. Without cooling, connectors and cables would fail quickly.

Tesla uses liquid-cooled cables and immersion-cooled connectors. This isn’t optional—it’s mandatory for safety and durability.

2) Battery Longevity

Charging at 1.2 MW equals a 1.4C charge rate for an 850 kWh battery.

That’s high for a truck expected to run hundreds of thousands of miles.

Tesla’s confidence comes from 4680 cells, designed for high current density and cooling efficiency.

3) Grid Impact

A single Semi charging at 1.2 MW is like powering a small neighborhood. Multiply that by multiple trucks, and the grid becomes a bottleneck.

That’s why Tesla uses on-site battery storage like Mega Packs to buffer demand and avoid peak charges.

The Shift to MCS Standard is a Big Deal

Early semi prototypes used proprietary connectors. That approach wouldn’t scale.

Tesla’s decision to adopt the Megawatt Charging System (MCS) standard is a major industrial shift.

MCS provides:

- Higher current tolerance

- Better thermal stability

- Improved safety

- Cross-manufacturer compatibility

This means future semis won’t be locked into Tesla-only infrastructure.

1.2 MW is Peak Power—Not Constant

Batteries follow a charging curve:

- Maximum power at low SOC

- Power tapers as the battery fills

To reach 70% in 30 minutes, Tesla must maintain a high charging curve at extremely high power.

Early tests show it’s achievable, but scaling across thousands of trucks and climate conditions remains the true challenge.

Charging Time Matches Driver Rest Periods

A Tesla Semi consuming 1.5 kWh per mile with an 850 kWh battery delivers about 500 miles of range.

Charging from 10% to 80% at megawatt speed takes roughly 30 minutes—perfectly aligned with mandated driver rest breaks.

Diesel trucks refuel in 15 minutes, but they stop more often. Electric trucks trade more frequent stops for longer, more productive rest-based charging.

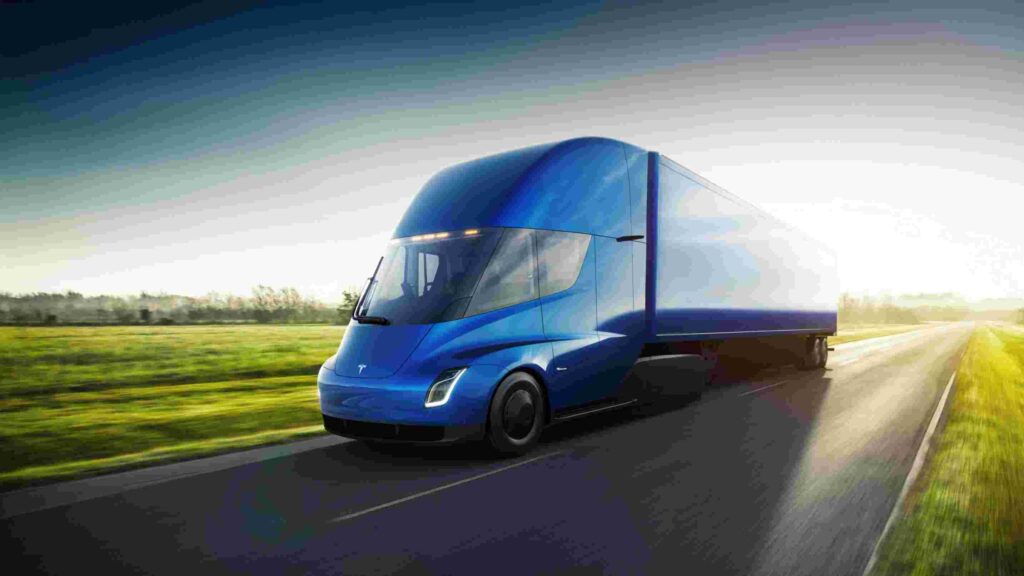

Tesla Semi Gen 2 is Designed for Mass Production

Tesla’s big reveal in early 2026 was not a prototype—it was a real production-intent vehicle: Semi Gen 2.

Tesla didn’t rely on a single breakthrough. It used industrial maturity:

- Better manufacturing

- Fewer parts

- Improved efficiency

- Stronger industrial foundation

Key Gen 2 Improvements

1. Updated exterior design

A new front light bar aligned with Tesla’s production ecosystem.

2. Better efficiency

Tesla reports 1.7 kWh per mile—about a 15% improvement.

3. Battery upgrade

Shift from LFP to 4680 high-voltage cells, offering ~300 Wh/kg energy density.

This allows same range with less weight, increasing payload capacity.

The Practical Reality of the Semi’s Range

Tesla kept the range at 500 miles intentionally.

Not because they couldn’t go further, but because it’s a commercially realistic decision.

A smaller battery reduces:

- Weight

- Cost

- Complexity

And improves:

- Payload capacity

- Efficiency

- Profitability

Semi Charging Strategy Matches Real Trucking Needs

The Semi can recover hundreds of kWh during mandatory rest breaks.

Instead of carrying a massive battery, the truck relies on fast predictable charging—a business model that makes sense for fleets.

Real World Validation

DHL’s trial covered 3,000 miles over two weeks:

- Full loads at 75,000 lb

- Average consumption: 1.72 kWh/mile

- Average speed above 50 mph

- Range: 390 miles under load

DHL estimates 50 tons of emissions reduction per truck per year, and plans to order more.

Tesla’s Industrial Strength Matters

Tesla’s success with the Model Y—world’s best-selling car for 3 years—proves Tesla’s manufacturing power.

The same approach now applies to the Semi:

- Simplification

- Vertical integration

- Scale

Tesla’s expansion at Giga Berlin shows long-term commitment, even during market challenges.

The Big Question: Will Battery Degradation Undermine the Semi?

With repeated megawatt charging, the risk is real.

But Tesla’s 4680 technology may have solved it.

The truth will be proven over time.

Conclusion

Tesla’s 1.2 MW charging test isn’t just a headline—it’s a signal that electric trucking has crossed a major technical threshold.

It shows that Tesla is not only building a fast truck but building a system that can support real-world long haul operations.

From thermal management to grid integration, Tesla is solving problems that other manufacturers have avoided.

And with the Semi Gen 2, Tesla is showing the world that electric heavy-duty trucking is not a future dream—it’s arriving now.

FAQs

1. What is the Tesla Semi?

The Tesla Semi is Tesla’s all-electric Class 8 truck designed for long-haul freight transport, featuring high performance, long range, and advanced energy efficiency.

2. What does 1.2 MW charging mean?

1.2 MW charging means the truck can receive 1,200 kilowatts of power, which is 4–5 times faster than the fastest consumer EV chargers.

3. Is 1.2 MW charging real or just a marketing stunt?

Tesla has demonstrated real-world charging at 1.2 MW, proving the system can support megawatt charging for heavy-duty trucks, not just on slides.

4. How long does it take to charge the Tesla Semi?

Tesla claims the Semi can recharge 70% in 30 minutes, enabled by megawatt-level charging.

5. Why is 1.2 MW charging important for trucking?

Long-haul trucking requires fast, predictable charging to match driver rest breaks. 1.2 MW charging allows trucks to recover range quickly without carrying oversized batteries.

6. Can the U.S. grid support 1.2 MW charging?

A single truck at 1.2 MW draws power comparable to a small neighborhood. So grid upgrades and battery storage are required for large-scale deployment.

7. What is MCS charging?

MCS (Megawatt Charging System) is the standardized charging connector designed for heavy-duty trucks, allowing cross-brand compatibility and safer high-power charging.

8. Why did Tesla switch to MCS?

Tesla switched to MCS to enable industry-wide charging compatibility, reduce fragmentation, and improve safety and reliability.

9. Does 1.2 MW charging damage the battery?

Repeated megawatt charging can stress batteries, but Tesla uses 4680 cells designed for high currents and improved cooling, reducing degradation risk.

10. How big is the Tesla Semi battery?

The Tesla Semi battery is estimated between 800–900 kWh, which is roughly 10 times larger than a typical electric car battery.

11. What range does the Tesla Semi offer?

Tesla’s Semi targets about 500 miles of range, which is ideal for long-haul freight routes.

12. Why did Tesla keep the range at 500 miles?

Tesla chose a practical range to reduce battery weight, cost, and complexity while maximizing payload and efficiency.

13. How does 1.2 MW charging affect trucking logistics?

It enables charging during mandated driver rest periods, making electric trucks operate similarly to diesel trucks without extra downtime.

14. Are liquid-cooled cables necessary for megawatt charging?

Yes. At 1.2 MW, cables generate extreme heat. Liquid cooling is essential to prevent damage and ensure safe operation.

15. What are the safety concerns with 1.2 MW charging?

High-power charging requires strict thermal monitoring and automated shutdown systems. Improper use or tampering can cause catastrophic failures.

16. How does Tesla improve Semi efficiency?

Tesla improved aerodynamics, drivetrain control, and battery chemistry, reducing energy consumption to about 1.7 kWh per mile.

17. What is Tesla’s Semi Gen 2?

Semi Gen 2 is the refreshed production-intent model with improved design, efficiency, and manufacturing readiness for 2026 production.

18. Who is testing the Tesla Semi in real life?

Companies like PepsiCo and DHL have already tested the Semi, confirming its real-world range and efficiency.

19. Will Tesla Semi replace diesel trucks?

Tesla aims to make electric trucking economically viable. If charging infrastructure scales, the Semi could significantly reduce diesel dependency in long-haul freight.

Read More:

- Elon Musk 2026 Model 2: Tesla Aluminum-Ion: 6× Faster Charging, 500+ Mile Range, Under $25k

- Elon Musk’s Boring Company studying potential Giga Nevada tunnel: report

- Samsung’s Tesla AI5/AI6 chip factory to start key equipment tests in March: report

- Tesla Model Y leads South Korea’s EV growth in 2025

- Tesla announces closure date on widely controversial Full Self-Driving program

- Tesla Robotaxi fleet reaches new milestone that should expel common complaint

1 thought on “Elon Musk Fixes 3 Tesla Semi Failure After 1.2 MW Charging Tests on U.S. Routes”