The journey to the Moon has always been fraught with engineering challenges, but the proposed methods by SpaceX for its lunar lander — the Starship HLS (Human Landing System) — may rewrite the rules of how we touch down on another world. In the standard version of Starship, the biggest technical challenge lies in its heat-shield tiles. But for the HLS version, the toughest part isn’t about heat. It’s all about the landing legs.

Yes: Even though SpaceX already has experience designing and landing rockets using legs (just look at the Falcon 9), the HLS is a whole different beast. It’s five times heavier and far more complex, making a reliable landing system a whole new challenge. That raises a big question: If it’s so hard, why not just get rid of the legs altogether? As Musk once put it, the best part is no part. That’s right — the HLS might actually be designed without landing legs. But how would it land on the Moon? Let’s find out.

Why Landing Legs Are Critical On the Moon

In lunar-lander history, every vehicle from the Luna 9 (1966) to NASA’s Apollo Lunar Module and even Blue Moon MK1 (by Blue Origin) has relied on landing legs. Not a single lander has ever touched down on the Moon without them. Their purpose is simple but critical: absorb the impact on touchdown and keep the vehicle stable on the Moon’s rough, uneven surface, blanketed with fine powdery regolith that can easily give way.

The same idea applies to Starship HLS. According to early design concepts, it should also have landing legs. But here’s the strange part: to this day, SpaceX has never revealed any official design diagram or even a 3D concept of what those legs might look like. That’s led many to wonder: is designing landing legs for the HLS really that difficult? The answer is: yes — it actually is.

The Scale Problem

The main problem comes down to scale. Starship HLS is enormous: ~9 m wide, ~52 m tall, and weighing around ~300 tons at landing (or equivalent) on Earth. Now imagine trying to safely set that down on the Moon’s surface — a world full of craters, rocks, and soft dust.

If you use traditional legs, they’d have to be extremely long and strong, adding several tons of dry mass to the vehicle. They’d also need special systems to prevent one leg from sinking into a soft patch of regolith, which could instantly tip the whole lander over. Even SpaceX’s experience with Falcon 9 doesn’t help much here: Falcon 9 uses four legs, lands on flat surfaces, deals with Earth’s gravity, and weighs in the landing stage at only ~22-25 tons. By comparison, the HLS under lunar gravity would weigh the equivalent of about 50 tons on Earth. But the landing site itself is far more dangerous — especially considering that HLS has a completely different design from traditional lunar landers: it’s much taller, which means its center of gravity is also much higher, making it far more susceptible to tipping over if anything goes wrong during touchdown.

Why Design Without Legs?

So, given all these challenges, why not skip the legs altogether and give Starship a completely different landing configuration? That was one of SpaceX’s original ideas when submitting its HLS proposals to NASA.

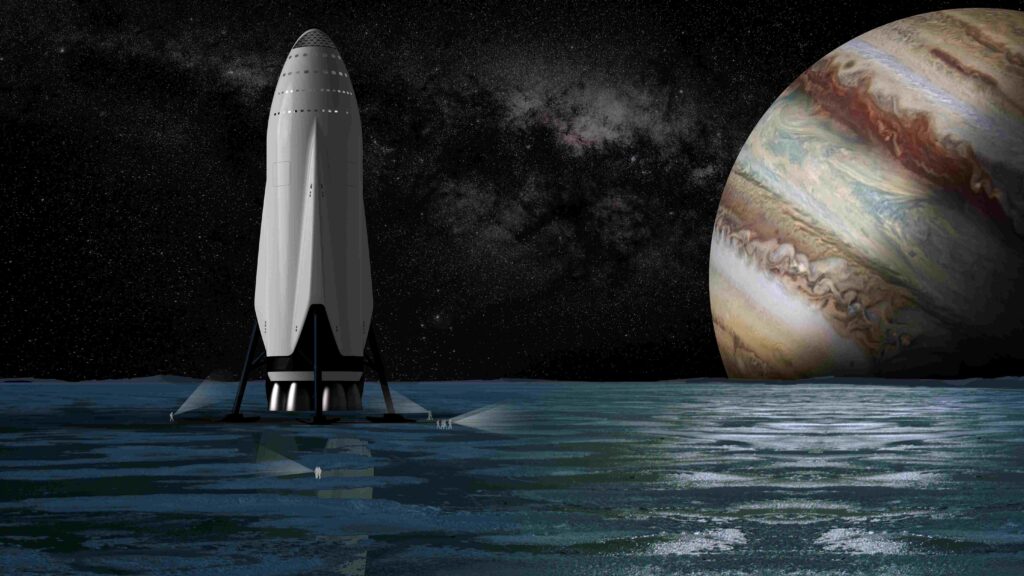

In April 2021, right after NASA awarded SpaceX the $2.89 billion option for the HLS contract, the Starship team unveiled a bold concept: a legless lander for the first time in over 60 years of lunar exploration. A crude lander would touch down without a single landing leg.

The Legless Concept

The idea came straight from Musk’s design philosophy: “the best part is no part.” Instead of adding 6 to 8 tons of folding legs, hinges, pistons, loads, sensors, cables, and pneumatic systems, SpaceX proposed using the entire base of the vehicle itself as the landing surface — essentially turning the 9 m wide Starship into one gigantic landing leg.

Key elements:

- The lower rim of the ship would be reinforced with an 8 mm thick titanium ring and a crushable skirt made of 3D-printed aluminum lattice about 40-50 cm thick.

- This layer would deform in a controlled way on impact, absorbing up to ~70% of the landing energy — similar to the honeycomb shock absorbers used on the Apollo lunar module, but fully integrated into the vehicle’s structure.

- It’s reminiscent of early Starship prototypes like SN10, which managed to land vertically without the kind of deployable legs used on Falcon 9.

Here’s how it would work:

- In the final ~10 seconds before touchdown, all six Raptor engines would throttle down to just ~5-8% of full power (roughly 10-5 tons of thrust per engine), producing just enough force to let Starship kiss the surface at a speed of less than 1 m/s.

- About 30-60 seconds earlier, a ring of hot-gas thrusters mounted around the base would fire at a 45° angle, blowing away the loose lunar dust and compacting the ground beneath it into a firm surface about 20-30 cm thick, effectively creating a compacted landing pad. This layer could withstand pressures of roughly 25 kilopascals (kPa) — about the same as the tire pressure of the Apollo lunar rover.

- SpaceX refers to this technique as Plume Surface Interaction (PSI). According to their CFD simulations, it could even level out slopes of up to ~10°, all without mechanical landing gear or digging equipment.

- In terms of mass: the legless “Option A” design would have a dry mass of around 85 tons, saving 8-10 tons compared to a version with legs. That weight reduction could be used to carry an additional ~7 tons of payload or extend crew operations by 3-4 extra days thanks to extra propellant capacity.

- All the complex hardware normally required for landing legs — six 12 m titanium struts, 24 hinges, 48 pneumatic pistons, 72 pressure sensors, 18 electric actuators — would be eliminated entirely. Thousands of potential failure points are gone, and assembly time shortened by nearly 30%. Simpler, faster, and more efficient. That’s exactly what SpaceX needs.

Alternative: Horizontal Landing

But wait — that’s not the only way to land without traditional landing legs. There’s another, even more radical approach: a horizontal landing. And no — this isn’t science fiction. It’s a legitimate engineering proposal designed to eliminate 10-15 tons of heavy landing gear entirely.

How the Horizontal Concept Works

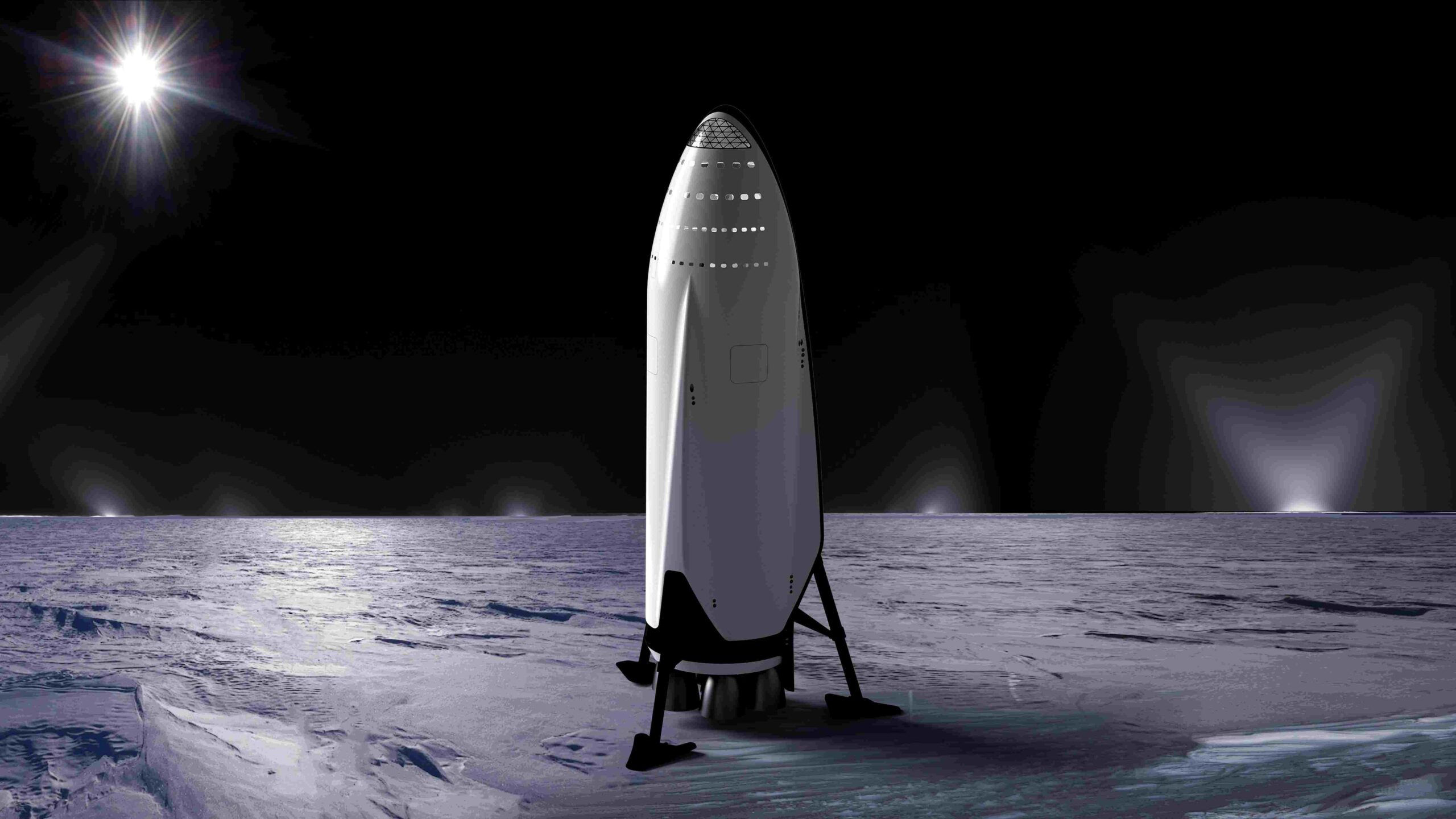

- The Starship HLS would still approach the lunar surface vertically (just like we’ve seen during test flights). Using its three Raptor vacuum-engines, it would slow down from ~1.6 km/s to just 2-3 m/s.

- When the ship reaches ~50 m above the ground, the Reaction Control System (RCS) — a network of 48 small thrusters — would fire gradually, tipping the vehicle from a 90° vertical position to about 30° over 10 seconds.

- A composite landing pad about 50 cm thick would deploy from the belly of the ship, cushioning the touchdown and absorbing impact to under ~3 g.

- The advantages: Landing horizontally spreads the contact area to roughly 160 m², distributing load to just ~0.3 kg per square cm. Compare that to a legged configuration where pressure might reach ~4 kg per square cm — enough to sink or tip the vehicle in soft lunar dust. It’s akin to walking on sand — the more surface area you spread your weight over, the less you sink.

- Additional benefits: For astronauts, this design would be far more practical. They could exit via a simple 3-meter folding ramp instead of relying on a 30-meter elevator system like in the original concept. A horizontally-landed Starship could serve as an instant lunar base: its 100 m³ interior volume would provide immediate living space; the ship’s surface could be covered with a layer of regolith blocking up to ~80% of cosmic radiation; side cargo doors could allow 2.5-ton rovers to roll directly out — no cranes needed.

Sounds brilliant, right? But as with everything in engineering, it comes with trade-offs.

The Hidden Trade-Offs

Structural & Operational Challenges

- Spacecraft internal structure: Most of the Starship’s internal structure was designed to handle vertical loads. Its tanks, cargo bays and internal framework might not withstand a horizontal orientation without reinforcement. That could cause pressure imbalances inside the propellant tanks, leading to sloshing or even leaks.

- Returning to orbit: A vehicle lying on its side cannot simply take off again. It has to stand upright again before launch — and lifting something that massive into position on the Moon is an enormous challenge.

- Best use case: Realistically, the horizontal landing concept makes more sense for cargo variants of Starship, not the crewed version. For missions like Artemis III, a vertical landing remains the most practical approach.

Institutional Resistance & Surface Risks

The idea of landing without legs has faced strong opposition — not just from engineers, but from NASA itself. During the Option A phase, both NASA and the Aerospace Safety Advisory Panel firmly rejected the concept in their Q4 2022 risk assessment report. They had good reasons:

- The lunar regolith isn’t uniform. The surface layer can vary from 4 to 12 m deep with sharp buried rocks underneath. If one side of the vehicle sinks just 1 to 1.5 m, the ship could tilt more than ~25° within 2 seconds — enough to topple even a 50-ton vehicle under lunar gravity.

- The plume-ejector problem: Even when throttled down, six Raptor engines still produce exhaust velocities exceeding ~2,000 m/s — easily capable of digging a 1-2 m crater beneath the vehicle. In effect, the thrusters destroy the compacted surface they are relying on. (Something already observed during NASA’s LCROSS experiment back in 2009.)

- No redundancy: Without landing legs, if even one of the six Raptor engines fails or its gimbal gets stuck, the vehicle would lose thrust balance and hit the ground at over ~5 m/s — far above the human-rated landing certification limit (which demands at least two-failure tolerances).

- Without landing legs, the crew cabin sits too close to the surface. Regolith dust kicked up during landing could cling to the underside of the ship and enter the cabin when the hatch opens, contaminating medical and air-filtration systems.

Because of all that, NASA issued a clear directive: A legged landing system with active terrain compensation is mandatory for “crude missions.” SpaceX had no choice but to pivot to Option B, starting in early 2023 — redesigning Starship with six retractable landing legs made from 3D-printed titanium lattice. Each leg would be 12-15 m long, weigh ~1.2–2 tons, and feature adjustable pistons for ~15° terrain compensation, crushable honeycomb dampers, and real-time LAR sensors to adapt automatically to uneven terrain.

Which Design Makes More Sense? Legless or Legged?

Pros & Cons Summary

Legless / Integrated-skirt concept

Pros:

- Significant mass savings (~8-10 tons) allowing for more payload or propellant margin.

- Fewer mechanical systems, fewer failure points.

- Simpler, potentially faster integration and less complex operations.

- Enables novel landing schemes (e.g., PSI, large base footprint) that circumvent some leg limitations.

Cons:

- High risk from uneven or unknown regolith properties.

- Large risk of crater formation beneath vehicle due to plume.

- Lack of redundancy in landing support system.

- Difficulties if one side sinks or terrain shifts.

- Unknown how well integrated “skirt” system can absorb energy and adapt on a slippery small-body surface.

Traditional legged concept (six large legs with terrain compensation)

Pros:

- Proven technology basis — legs have been used by previous lunar landers.

- Better capability to adapt to uneven terrain via terrain-sensing and compensation.

- Reduces risk of tipping.

- Institutional acceptance (NASA is more comfortable with them).

Cons:

- Added mass (several tons) reduces payload/propellant margin.

- More mechanical complexity means more potential points of failure.

- More integration and testing required.

- Very large lander means legs must be extremely strong, extremely reliable, and must deploy under lunar gravity with little or no margin for error.

My Take

For a crewed lunar landing mission — especially one undertaken by NASA with human lives and a public reputation on the line — it makes sense to err on the side of redundancy and reliability. That means the legged design appears more prudent given today’s constraints and risk-tolerance.

However, from a purely visionary engineering-andmass-efficiency standpoint, the legless concept is beautiful — and perhaps will find its place in future cargo or base-establishment missions on the Moon or Mars. The key will be proving that the technique works reliably on the lunar surface, with its unknowns and dust behavior.

Why Heat Shields Still Matter (Even Though HLS Has Them Less)

While the discussion about landing legs dominates the HLS conversation, we must not forget the other end of the challenge: the heat shield. That is, for the standard Earth-return version of Starship, the heat shield remains a massive technical hurdle. For HLS, some aspects are simplified (since it doesn’t need to re-enter Earth’s atmosphere), yet the overall vehicle still needs a reliable system for the lunar environment and possible Earth return (depending on mission architecture).

- SpaceX has publicly acknowledged that the “biggest remaining problem” for reusable Starship (Earth version) is making a reusable orbital return heat shield. The Tech Portal+2Genspark+2

- The standard Starship uses ~18,000 hexagonal ceramic tiles on its windward side. India Today+1

- For the HLS version, NASA documents indicate that it does not have a heat shield or flight control surfaces, because it never needs to survive Earth-atmosphere re-entry. University of Cincinnati+1

- That suggests that while legs (or lack thereof) capture headlines, we should not underestimate how much SpaceX has simplified other aspects of the HLS by removing the return heating burden.

So in summary: the standard Earth-return Starship wrestles with heat-shield tile durability, attachment issues, gap-sealing and re-entry thermal loads. But the HLS’s biggest headache may well be how to land a massive vehicle without tipping over, sinking, or failing structurally — hence the leg-versus-no-leg debate.

What’s Next? The Road to a Moon Landing

Before HLS can ever touch the lunar surface, there are still some massive hurdles to overcome:

- Perfecting the landing on Earth first: While Earth gravity is ~6 × lunar gravity, and atmosphere introduces additional complexity, the landing systems still must prove themselves under real flight conditions.

- Proving the orbital refueling system: The HLS mission profile requires in-space refueling (e.g., tanker Starship launches to top off HLS in orbit) so that it has enough propellant to land, stay, and lift off again from the Moon. Without that capability, there is simply no path.

- Demonstrating surface operations: Whether lander legs deploy (or don’t), the spacecraft must deal with lunar regolith, dust mitigation, crater formation from plumes, and the challenges of a tall, narrow lander footprint (if legless) or high-mass legs (if legged).

- Developing crew-rated systems: Life support, radiation protection, abort modes, redundant systems — all must be proven safe.

- Getting NASA approval & certification: NASA’s risk assessment has already pushed back the legless concept. SpaceX must satisfy NASA’s criteria for human-rated lunar landing.

Conclusion

The debate over whether the Moon-bound Starship HLS should land with legs or without legs is more than a design quirk: it’s a window into how radically different lunar landing architecture is when compared to Earth-based reusable rockets, and how cutting-edge the engineering must be. The legless concept is bold, innovative, and promise-rich. The legged concept is conservative, reliable, and mission-safe.

Given the scale of the HLS, the risk of tipping, sinking, plume damage, and mechanical failure is real. NASA’s caution is prudent. But if SpaceX can prove a legless or horizontally landing design works reliably, the payoff — mass savings, payload capacity, simpler systems — could be game-changing for lunar and Mars missions.

So: What do you think? Which design makes more sense for you, a legless Starship HLS or one with retractable landing legs? I’d love to hear your thoughts below.

Of course, before we get there — the heat shields still need work, orbital refueling must succeed, and the entire ecosystem of deep-space operations must mature. The next few years will be fascinating.

FAQs

1. What is SpaceX’s Starship HLS?

The Starship HLS (Human Landing System) is SpaceX’s specially modified version of Starship, designed to land astronauts on the Moon under NASA’s Artemis program. Unlike the standard Starship, the HLS is optimized for lunar operations — no heat shield, no flaps, and possibly even no landing legs.

2. Why is the landing system such a big challenge for Starship HLS?

Because the HLS is enormous — about 52 meters tall and 9 meters wide — landing safely on the Moon’s uneven, dusty surface is incredibly difficult. Traditional landing legs would need to be very long, strong, and heavy, increasing total mass by several tons.

3. Did SpaceX really propose a Starship without landing legs?

Yes. Elon Musk’s team originally proposed a legless Starship that would land directly on its reinforced base. This bold idea followed Musk’s design philosophy: “The best part is no part.” The concept aimed to save 8–10 tons of weight and reduce mechanical complexity.

4. How could a legless Starship land safely on the Moon?

In this concept, the entire base of Starship acts as a giant landing pad. Reinforced with titanium and aluminum lattice, it would absorb impact like a crushable shock absorber. Hot-gas thrusters would also compact the lunar dust before touchdown, creating a stable pad.

5. What is “Plume Surface Interaction (PSI)” and how does it work?

Plume Surface Interaction (PSI) refers to how Starship’s engine exhaust interacts with the lunar soil. SpaceX’s PSI design uses angled thrusters to blow away loose regolith and compact the landing zone moments before touchdown — reducing the chance of sinking or tipping.

6. How heavy is Starship HLS compared to the Falcon 9?

The Falcon 9 weighs around 22–25 tons at landing, while the HLS Starship will weigh the equivalent of ~50 tons under lunar gravity — or about 300 tons on Earth. That’s why simple Falcon-style legs aren’t enough for lunar operations.

7. What are the advantages of removing landing legs?

Eliminating legs saves mass and mechanical complexity, freeing up room for more payload or extra fuel. It also reduces potential failure points — no hinges, pistons, actuators, or sensors needed. Simpler systems mean fewer things can go wrong in space.

8. What are the risks of a legless lunar landing?

Without legs, the lander has no redundancy if one area sinks into soft dust. It could tip over, suffer from crater formation due to exhaust, or experience engine imbalance during touchdown. These are major risks for human-rated missions.

9. Why did NASA reject the legless Starship design?

NASA’s Aerospace Safety Advisory Panel determined in 2022 that a legless HLS was too risky. They cited issues with uneven regolith, engine plume cratering, and lack of redundancy. NASA required SpaceX to switch to a legged design for safety.

10. What does the current legged Starship design look like?

The latest concept includes six retractable landing legs made from 3D-printed titanium lattice. Each leg is around 12–15 meters long, equipped with hydraulic pistons, crushable dampers, and real-time sensors to adapt to uneven lunar terrain.

11. What is the horizontal landing concept for Starship?

Another radical idea SpaceX explored is horizontal landing — tipping Starship onto its side before touchdown. This spreads weight across a wide base, reducing ground pressure. It could also make astronaut egress and cargo unloading much easier on the lunar surface.

12. Why can’t Starship take off horizontally from the Moon?

Because its propellant tanks and structure are designed for vertical loads. A horizontal position could cause fuel imbalance, leaks, or sloshing, and standing it upright again would require enormous energy and specialized equipment — impractical for crew missions.

13. What makes the Moon’s surface so difficult to land on?

The lunar regolith is a fine, powdery dust that can be several meters deep. It hides sharp rocks and offers uneven traction. Engine exhaust can blast away this dust, forming craters or uneven surfaces. Stability and dust control are major engineering hurdles.

14. How does the Starship HLS differ from the standard Starship?

Unlike the Earth-return Starship, the HLS has:

- No heat shield or flaps (it never re-enters Earth’s atmosphere)

- Larger fuel reserves for lunar descent/ascent

- Modified interiors for crew habitation

- A dedicated landing system for the Moon’s terrain

15. When will SpaceX’s Starship HLS land astronauts on the Moon?

NASA’s Artemis III mission aims to land astronauts on the Moon using SpaceX’s Starship HLS in the late 2020s. However, the timeline depends on successful orbital refueling, flight testing, and NASA certification. Before that, SpaceX must perfect Starship’s Earth landings and refueling systems.

Read More:

- Tesla Cybertruck explosion probe ends with federal involvement and new questions

- Tesla investors are ditching Charles Schwab after its vote against Musk comp plan

- 2026 Tesla Pi Phone OFFICIALLY Here: Elon Musk Announces Free Starlink for the Masses

- SpaceX finally exposed this after ex-NASA Chief Criticizes Starship HLS Unnecessary

- Tesla begins wide rollout of Full Self-Driving v14 to Cybertruck

1 thought on “Elon Musk’s Insane Starship Moon Landing Method Shocked NASA: Skip Legs”