SpaceX’s Raptor 3 engine has arrived as a symbol of the future in rocket propulsion—a marvel of power, precision, and innovation. However, despite its cutting-edge design, Elon Musk recently admitted that this engine still carries significant challenges within its core. So, what are these hidden flaws, and how will SpaceX overcome them? This post dives deep into the complexities behind Raptor 3 and explores its role in SpaceX’s Starship program.

The Evolution from Raptor 2 to Raptor 3

The Raptor 2 engine has flown on multiple missions but has consistently shown operational issues on both the Superheavy booster and the Starship vehicle itself. These problems mostly come from the engine’s complex internal design, which includes many delicate and fragile components prone to malfunction. This complexity makes the engine difficult to operate and maintain.

In response, SpaceX has shifted focus to developing a more powerful, refined version—Raptor 3. This new engine is designed to fix the shortcomings of Raptor 2 and push the performance envelope further.

What Makes Raptor 3 Different?

Since its debut, particularly during the launch campaign last August, Raptor 3 has been visually distinct thanks to its sleek and minimalist design. SpaceX has eliminated much of the intricate piping and delicate parts found in earlier versions, opting for structural simplicity.

This change is expected to bring several benefits:

- Improved reliability

- Reduced manufacturing and refurbishment time

- Better reusability

Key performance metrics such as thrust and specific impulse have also improved in testing, making Raptor 3 one of the most anticipated developments in the Starship system.

Elon Musk’s Revelation: A Complex Startup Sequence

Despite its seemingly simplified design, Elon Musk recently revealed on his social platform X (formerly Twitter) that the startup mechanism of Raptor 3 remains extremely complex. He stated:

“Very complex startup sequence. Insane timing precision is needed to avoid blowing up the engine.”

This statement was surprising because many expected the startup to be streamlined. Instead, the engine’s inner workings remain a major engineering challenge, especially in achieving perfect timing during ignition.

Why Is Starting Raptor 3 So Difficult?

Raptor 3, like its predecessors, uses a full flow staged combustion cycle powered by liquid methane and liquid oxygen—one of the most sophisticated engine cycles in rocketry. This cycle offers high performance and reusability but requires a highly precise sequence of events during startup.

Here’s a simplified breakdown of this complex startup process:

Engine Chill

The engine must first be cooled to prevent thermal shock when exposed to cryogenic propellants. This involves managing fuel flow and pressure with great precision to avoid creating damaging air bubbles.

Spin-Up Phase

Two turbo pumps—one for liquid methane and one for liquid oxygen—are spun up to high speeds in perfect synchronization. Each pump feeds fuel to its respective pre-burner, where a small portion burns to power the turbines.

Pre-Burner Ignition

This critical moment requires correct fuel ratios and flow rates. A “hard start” (a sudden uncontrolled ignition) here can cause severe damage.

Main Combustion Chamber Ignition

The hot gases from the pre-burners enter the main combustion chamber, where the remaining fuel and oxygen combust to produce thrust. The transition between pre-burner and main chamber ignition must be perfectly timed within milliseconds.

Continuous Monitoring

Once at full power, the engine’s avionics monitor dozens of variables including temperature, pressure, and fuel flow. Any anomaly can reduce efficiency or cause failure.

The Challenge of Engine Clusters

Starship and its booster don’t rely on a single Raptor engine—they use clusters of Raptors (up to 33 engines on the Superheavy booster). This means every engine must start, run, and shut down in perfect synchronization, making the system exponentially more complex.

Welding vs. Traditional Components: A Double-Edged Sword

To simplify and reduce weight, SpaceX removed traditional engine components like bolts and flanges, replacing them with an almost entirely welded structure.

Pros of Welding

- Increased structural integrity

- Fewer potential points of failure (like leaks)

Cons of Welding

- Lack of serviceability: Once welded, the engine cannot be easily disassembled. If a part deep inside needs replacing, technicians must cut the engine open—compromising its structure and increasing repair time.

This maintenance challenge conflicts with SpaceX’s goal of rapid reuse, where engines are flown, landed, refurbished quickly, and flown again. To succeed, SpaceX must aim for extremely high engine reliability to reduce the need for repairs.

Potential Solutions for Raptor 3 Challenges

SpaceX is actively working to address these issues with various strategies:

1. Refining the Startup Sequence

Automating and grouping startup actions could reduce timing errors, making the ignition sequence more reliable and easier to diagnose.

2. Sensor Upgrades and Smart Diagnostics

Installing advanced sensors for real-time telemetry will monitor every critical variable and allow instant automated reactions to anomalies, improving safety and efficiency.

3. Rethinking Maintenance

Although welding reduces failure points, SpaceX may develop modular internal units accessible through removable panels, enabling limited repairs without full disassembly.

4. Mass Production of Engines

Instead of focusing solely on repairs, SpaceX could mass produce Raptor 3 engines to replace faulty units quickly. This aligns with their vision of rapid Starship flight cadence but raises questions about long-term sustainability.

What’s Next? Looking Ahead to Raptor 4

On the horizon is the Raptor 4 engine, rumored to produce between 330 and 335 tons of thrust—significantly more powerful than Raptor 3.

Potential Improvements in Raptor 4

- Even higher thrust (possibly enabling Starship to exceed 10,000 tons of liftoff thrust)

- Cleaner and simpler startup logic

- Better serviceability and modularity

- Seamless integration with future Starship designs

Raptor 4 aims to build on Raptor 3’s lessons while continuing to emphasize simplicity and reliability.

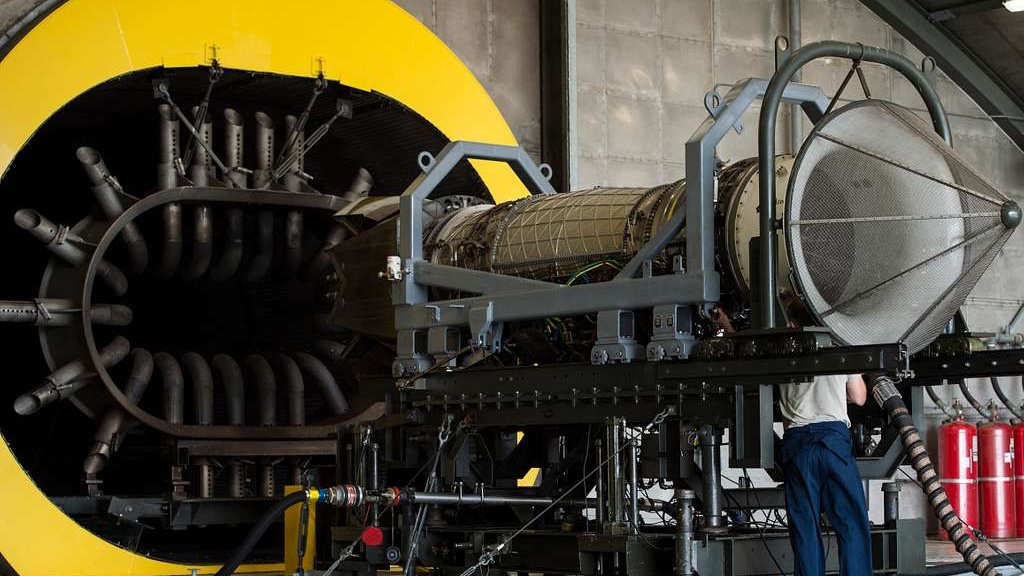

Recent Testing and Incident Reports

Raptor 3 is currently undergoing rigorous testing at SpaceX’s McGregor facility. Recently, a reported engine explosion during testing sparked concerns. However, it’s important to note:

- SpaceX frequently pushes engines beyond limits to identify failure points.

- Such incidents may be intentional as part of the validation process.

- There is no official indication that Raptor 3 development is in serious trouble.

How Does Raptor 3 Compare to Competitors?

Among its main rivals, Blue Origin’s BE-4 engine is often compared to the Raptor series. Both use liquid methane and target reusability with fast turnaround.

Key Differences

| Feature | Raptor 3 | BE-4 |

|---|---|---|

| Thrust (sea level) | ~280 tons | 250 tons |

| Chamber Pressure | ~350 bar | ~134 bar |

| Engine Count on Rocket | Up to 33 (Superheavy) | 7 (New Glenn) |

| Production Rate | About 1 per day | Weeks to months unknown |

| Rocket Liftoff Thrust | ~9,000 tons (projected) | 1,750 tons |

Raptor 3 outperforms BE-4 in thrust, chamber pressure, and production efficiency. This gives SpaceX a significant edge for high cadence launches and ambitious missions like lunar exploration and Mars colonization.

Why Is Raptor 3 Critical to SpaceX’s Future?

Raptor 3 is not just another engine iteration; it’s a statement of intent for SpaceX’s goals of:

- Making Starship a fully reusable spacecraft

- Supporting a high launch cadence

- Enabling missions to the Moon, Mars, and beyond

- Maintaining a competitive edge in aerospace

Its success will shape the future of space exploration.

When Can We Expect to See Raptor 3 in Action?

Raptor 3 is slated to debut on Starship V3 prototypes, specifically B18 and S39, with a critical flight expected before the end of the year. This flight will provide invaluable in-flight data on Raptor 3’s performance and durability.

Conclusion: The Marvel and Challenge of Raptor 3

Raptor 3 is a technological marvel pushing the limits of rocket engine design. Its simplified exterior masks a complex and demanding inner system, requiring insane timing and precision.

While the challenges are significant—especially in startup complexity and maintenance—SpaceX is poised to overcome them through innovation, automation, and production scale.

As Raptor 3 moves closer to operational status, it represents a major leap forward for the Starship program and spaceflight as a whole.

FAQs

1. What is the SpaceX Raptor 3 engine?

The Raptor 3 is the latest iteration of SpaceX’s full flow staged combustion rocket engine, designed to power the Starship vehicle and Superheavy booster with higher thrust and improved reliability.

2. How is Raptor 3 different from Raptor 2?

Raptor 3 features a simplified, mostly welded design with fewer fragile components, improved thrust, and aims to resolve operational issues seen in Raptor 2 engines.

3. Why did Elon Musk say the Raptor 3 startup is complex?

Musk revealed that the ignition sequence requires extremely precise timing to avoid engine failure, making startup one of the biggest technical challenges.

4. What fuels does Raptor 3 use?

Raptor 3 runs on liquid methane (CH4) and liquid oxygen (LOX), a combination known as methalox, which supports efficient, reusable rocket engines.

5. What is a full flow staged combustion cycle?

It’s a rocket engine cycle where all propellants pass through turbines before combustion, maximizing efficiency and performance but requiring precise engineering.

6. Why is welding used instead of bolts in Raptor 3?

Welding reduces leaks and improves structural strength but makes maintenance and repairs more difficult since the engine isn’t easily disassembled.

7. What are the main challenges in maintaining Raptor 3 engines?

Because of the welded design and complex internal parts, repairing internal damage requires cutting open the engine, which is time-consuming and costly.

8. How many Raptor engines are used on the Starship Superheavy booster?

The Superheavy booster is expected to have up to 33 Raptor engines working in a coordinated cluster during liftoff.

9. What happens if one Raptor engine fails during launch?

SpaceX designs its engines and flight software to handle engine failures, but synchronized operation is critical to mission success, making reliability essential.

10. What improvements are expected in the upcoming Raptor 4 engine?

Raptor 4 aims for higher thrust (up to 335 tons), simpler startup procedures, better modularity for maintenance, and integration with future Starship designs.

11. Has Raptor 3 faced any explosions or failures during testing?

Yes, some engines have exploded during testing as SpaceX pushes limits to identify failure points and improve designs, which is a normal part of development.

12. How does Raptor 3 compare to Blue Origin’s BE-4 engine?

Raptor 3 produces higher thrust and chamber pressure, and it’s designed for faster production rates, giving SpaceX an edge in reusability and launch cadence.

13. Why is the startup sequence timing so critical for Raptor 3?

Precise timing prevents “hard starts” or explosions caused by incorrect fuel/oxidizer ratios and pressure during ignition, ensuring engine safety.

14. Can Raptor 3 engines be reused quickly after landing?

SpaceX aims for rapid reuse, but the welded structure and startup complexity mean high engine reliability is needed to minimize time-consuming repairs.

15. When will Raptor 3 fly on a Starship mission?

Raptor 3 is expected to debut on Starship prototypes B18 and S39, possibly by the end of this year, providing crucial flight data.

16. How does the welded design affect engine production?

Welding speeds up production and reduces assembly errors but complicates post-production repairs, so SpaceX must balance manufacturing and maintenance needs.

17. What role does Raptor 3 play in SpaceX’s Mars ambitions?

Raptor 3’s high thrust and reusability are key to enabling Starship’s heavy lift capabilities, critical for transporting cargo and humans to Mars.

Read More:

- Elon Musk shares details on Tesla AI6 production deal with Samsung

- Tesla’s new affordable Model Y details teased in new sighting

- Tesla hints a smaller pickup truck could be on the way

- 2026 Tesla Model 2: Elon Musk Announces SHOCKING Truth. Not Cheap AT ALL

- SpaceX officially announced NEW Major Design Cargo Starship To The Moon

1 thought on “TOO COMPLEX! Elon Musk revealed Why SpaceX Raptor Facing Hard Inside Problem”