The Tesla Semi Truck has always been one of the most anticipated vehicles in the EV world. Now, after nearly a decade since its first reveal, the revolutionary truck is finally ready to enter mass production in 2026. Elon Musk and his engineering team have made some jaw-dropping updates that make the Semi not only more powerful and efficient but also cheaper and easier to produce on a large scale.

This article dives deep into the Tesla Semi Gen 2, exploring its new aerodynamic design, upgraded 4680 battery, advanced Giga Press manufacturing process, and autonomous driving capabilities that could reshape the future of heavy-duty transport forever.

The Long-Awaited Tesla Semi Enters Mass Production

For years, the Tesla Semi has remained somewhat of a mystery. Despite its debut nearly nine years ago, only a limited number of units have been produced. Early prototypes were primarily delivered to large companies like PepsiCo for pilot testing, leaving most logistics businesses waiting for broader availability.

But that’s about to change. According to Dan Priestley, Tesla’s lead engineer and program development head for the Semi, the mass production line is finally completed. Starting next year, anyone—not just major logistics companies—will be able to order the Tesla Semi.

What’s more exciting? Priestley revealed that the new version will be cheaper thanks to a more efficient manufacturing process. Tesla’s latest factory now houses a next-generation production line capable of building a Semi truck in just minutes, instead of the months it previously required.

“Ultimately, we’ll make over a million—millions, probably—of the Tesla Semi,” Priestley stated. “You’ll see them all over the place, and eventually, they’ll also have autonomous capabilities.”

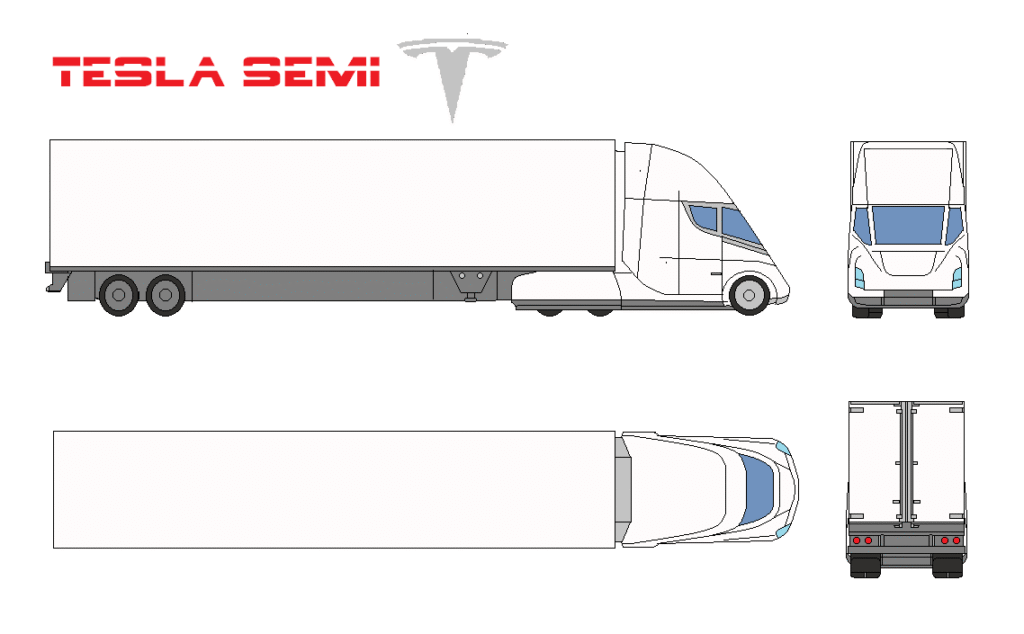

Aerodynamic Redesign: Inspired by Japan’s Fastest Train

From day one, Tesla designed the Semi to be the most aerodynamic and fastest electric truck in the world. Tesla’s chief designer, Franz von Holzhausen, took inspiration from Japan’s Shinkansen bullet train, giving the Semi its sleek, futuristic profile.

With the 2026 Gen 2 version, the aerodynamics are even better. The new Semi boasts a drag coefficient of just 0.36, around 30% lower than traditional diesel trucks—a huge leap for energy efficiency. This improvement translates to a 7% boost in range and performance, making the Semi even more dominant on highways.

Battery Revolution: Introducing Tesla’s 4680 HV Cells

One of the biggest updates for the Tesla Semi Gen 2 is its new high-voltage 4680 battery system. Until now, the long-range version of the Semi used an 800 kWh NMC (nickel manganese cobalt) battery pack, while the short-range “Semi Light” relied on LFP (lithium iron phosphate) cells.

But Tesla’s next-gen Semi will feature its most advanced battery yet—the 4680 HV cell. These cylindrical cells are engineered for higher energy density (up to 300 Wh/kg) and lower production costs due to their innovative structural battery design.

Despite having a smaller battery pack, the Gen 2 Semi will maintain the same impressive range, thanks to better aerodynamics, weight reduction, and powertrain optimization.

Key benefits of the 4680 HV battery:

- Lighter and more efficient design

- Cheaper to produce and maintain

- Higher power output per cell

- Increased longevity and safety

With Tesla manufacturing these cells directly at the Nevada Gigafactory, the production process becomes even more streamlined and cost-effective. It’s no longer just about innovation—it’s about scalability.

Improved Visibility and Safety: Cameras, Mirrors, and Drop Glass

Another fascinating area of improvement lies in the Semi’s visibility and safety features. Current Tesla Semi prototypes use side mirrors with integrated cameras, streaming live footage to dual 15-inch cabin displays. This provides 360° visibility with zero blind spots.

For the Gen 2, Dan Priestley hinted at smaller, more aerodynamic mirrors paired with smarter camera systems. These refinements will make the Semi even sleeker while maintaining (and potentially enhancing) driver visibility.

Tesla is also introducing a new drop glass window—a practical feature allowing drivers to hand off documents or communicate through checkpoints without opening the entire door. It’s a small change, but one that reflects Tesla’s focus on real-world functionality for truckers.

A New Face: LED Light Bar and Modernized Design

Recent reports from Next Big Future highlight that the updated Tesla Semi will feature:

- A redesigned front end with a sleek LED light bar

- Reworked headlights positioned below the light bar

- Refined aerodynamic surfaces

- Optional sleeper cab for long-haul comfort

The new design not only gives the truck a modern, high-tech look but also boosts its energy efficiency and brand identity. Elon Musk appears to be making the light bar a signature Tesla design element, as seen in other vehicles like the Cybertruck.

The Return of the Sleeper Cab: Comfort Meets Performance

One of the biggest requests from professional drivers has finally been addressed: the Tesla Semi will come with an integrated sleeper cab.

Long-haul drivers spend countless hours on the road, and fatigue is one of the leading causes of trucking accidents. Tesla’s sleeper cab will provide a comfortable rest area, turning the Semi into a true long-distance hauler.

While Tesla hasn’t revealed the exact design yet, experts believe it could either extend the cabin or reconfigure the existing interior layout to create a cozy sleeping area. This makes the Semi not only powerful and efficient but also driver-friendly.

Supervised Full Self-Driving (FSD) Coming to Tesla Semi Gen 2

Perhaps the most groundbreaking feature of the Tesla Semi Gen 2 is the integration of Full Self-Driving (FSD) technology. Starting with the 2026 model, Tesla plans to introduce supervised autonomy for the Semi.

This doesn’t mean the truck will drive completely on its own just yet—but it will be able to handle most highway routes autonomously with the driver monitoring the system. Using Tesla’s advanced AI, sensor suite, and neural networks, the Semi will navigate safely through highways, traffic, and loading docks.

Benefits of supervised FSD for trucking:

- Reduced driver fatigue

- Longer operating hours

- Lower accident rates

- Improved logistics efficiency

However, Tesla’s move into AI-driven freight transport also raises challenges. Regulators, insurers, and driver unions will scrutinize how autonomous trucks interact with human drivers on public roads. Still, if Tesla proves the technology is safer than humans, it could revolutionize the entire freight industry.

Cost and Affordability: How Tesla Will Lower Prices

Despite the massive technological upgrades, Tesla is focused on making the Semi more affordable. The new automated production line, combined with Gigapress technology and 4680 cells, will dramatically cut down manufacturing time and costs.

While the Gen 2 Semi may initially cost slightly more due to new components and FSD integration, prices are expected to drop significantly as production scales up—similar to what Tesla achieved with the Model 3 and Model Y.

In the long run, the total cost of ownership (TCO) for the Tesla Semi will be far lower than diesel alternatives, thanks to:

- Zero fuel expenses

- Minimal maintenance

- Fewer moving parts

- Longer lifespan of EV components

That’s why many logistics companies are preparing to switch to Tesla’s electric fleet once mass production begins.

Gigapress Revolution: Building a Semi in Minutes

One of Tesla’s greatest manufacturing breakthroughs is the Gigapress—a gigantic die-casting machine that can produce entire vehicle frames in one piece.

Until now, most Tesla Semis were assembled manually, with numerous welded and bolted components. This method was slow and expensive. But the new Gigapress at Giga Nevada changes everything.

The Semi’s dedicated Gigapress is rumored to be Tesla’s largest ever, capable of producing massive aluminum structures strong enough for heavy-duty use. This process allows Tesla to:

- Produce a Semi chassis in just 20 minutes

- Eliminate hundreds of assembly steps

- Improve precision and structural integrity

- Reduce weight and vibration

Elon Musk once said, “You can’t understand Tesla if you don’t understand the Gigapress.”

And for the Semi, it’s true—this innovation is the missing piece that makes mass production feasible.

Tesla’s Path to 50,000 Semis Per Year

With the new Gigapress in place and Giga Nevada’s 4 million sq. ft. expansion, Tesla aims to reach 50,000 Semi units per year by 2026. While ambitious, it’s now a realistic goal.

Experts predict that Tesla could start with 20,000 units in 2026, ramping up to full capacity in subsequent years. Once the automated production system stabilizes, Tesla could dominate the electric trucking market—a space that remains largely untapped by competitors like Volvo and Daimler.

Environmental Impact: Zero-Emission Trucking Future

Each Tesla Semi replaces a diesel truck that emits tens of tons of CO₂ annually. If Tesla successfully deploys tens of thousands of units, the environmental benefits will be enormous:

- Cleaner air quality

- Reduced greenhouse gas emissions

- Lower noise pollution

- A sustainable logistics ecosystem

The 500-mile range, 0–60 mph acceleration in 20 seconds, and energy efficiency of just 1.7 kWh per mile make the Tesla Semi the most capable electric truck ever built.

Paired with Megachargers that can charge to 80% in 30 minutes, the Semi isn’t just an idea—it’s a ready-to-drive revolution.

Challenges Ahead: Regulations, Costs, and Public Perception

While everything looks promising, Tesla still faces challenges before the Semi fully takes over highways worldwide:

- Regulatory approvals for autonomous driving in commercial trucks.

- Public trust in AI-driven freight systems.

- High initial infrastructure costs for charging and maintenance.

- Supply chain stability for large-scale battery production.

However, Tesla has overcome similar barriers before with the Model 3, Cybertruck, and Model Y—proving that patience and innovation can conquer the impossible.

Final Thoughts: Tesla Semi Gen 2 Marks a New Era in Transportation

The upcoming 2026 Tesla Semi Gen 2 isn’t just another vehicle—it’s the future of heavy-duty transport. From its aerodynamic bullet-train-inspired design to the next-gen 4680 batteries, Gigapress manufacturing, and supervised autonomy, every upgrade represents a leap toward a cleaner, smarter, and more efficient logistics world.

If Tesla delivers on its promises, we could soon see electric fleets replacing diesel across highways, transforming how goods are transported forever.

FAQs

1. When will the 2026 Tesla Semi Truck enter mass production?

Tesla is expected to begin mass production of the Semi Truck in 2026, following the completion of its new Gigapress-based manufacturing line at Giga Nevada. Initial large-scale deliveries could start by late 2026.

2. What makes the 2026 Tesla Semi different from earlier prototypes?

The Tesla Semi Gen 2 features major upgrades, including a smaller but more efficient 4680 HV battery, improved aerodynamics (drag coefficient 0.36), new LED light bar design, and supervised Full Self-Driving (FSD) capabilities.

3. How far can the Tesla Semi travel on a single charge?

The long-range version of the Tesla Semi offers an impressive 500-mile range on a single charge, thanks to its 800 kWh battery pack and highly efficient electric powertrain.

4. What type of battery does the Tesla Semi Gen 2 use?

The 2026 Tesla Semi Gen 2 will be powered by Tesla’s 4680 high-voltage battery cells. These cells have an energy density of 300 Wh/kg and offer higher efficiency, lower costs, and longer lifespan compared to earlier battery technologies.

5. How fast is the Tesla Semi?

The Tesla Semi can accelerate from 0 to 60 mph in just 20 seconds—even while fully loaded. That’s significantly faster than any traditional diesel semi-truck on the road.

6. Will the Tesla Semi have autonomous driving?

Yes. The Gen 2 Tesla Semi will debut with supervised Full Self-Driving (FSD) technology. This allows the truck to drive autonomously on highways, while the driver remains present for oversight and safety.

7. What is the drag coefficient of the new Tesla Semi?

The 2026 Tesla Semi achieves an industry-leading drag coefficient of 0.36, roughly 30% better than diesel trucks, improving both range and energy efficiency.

8. How much will the Tesla Semi cost?

Tesla hasn’t confirmed the final price of the 2026 Semi Gen 2, but experts expect it to start around $180,000–$200,000 for the long-range version. Prices are likely to decrease as production scales up.

9. What is the Tesla Semi’s charging time?

Using Tesla’s Megacharger network, the Semi can charge up to 80% in just 30 minutes, providing hundreds of miles of range in less than the average trucker’s rest break.

10. How does the Gigapress help Tesla build the Semi faster?

The Gigapress is a giant die-casting machine that allows Tesla to build large structural components in a single piece. This reduces production time from hours to minutes, lowers costs, and improves structural integrity.

11. Will the Tesla Semi include a sleeper cab for long-haul trips?

Yes. Tesla has confirmed plans for a sleeper cab version of the Semi, designed for multi-day trips. It will include a comfortable sleeping area, allowing drivers to rest during long hauls.

12. How will the new Tesla Semi improve trucking safety?

The Semi includes advanced driver-assistance systems, 360° camera coverage, improved mirrors and sensors, and FSD capabilities. Together, these features aim to reduce accidents and driver fatigue on long routes.

13. What companies are expected to use the Tesla Semi first?

Several large companies, including PepsiCo, Walmart, and FedEx, have already shown interest or received early prototypes. Once mass production begins, smaller logistics fleets will also be able to place orders.

14. What are the environmental benefits of the Tesla Semi?

Each Tesla Semi replaces a diesel truck that emits tens of tons of CO₂ per year. By switching to electric fleets, logistics companies can significantly cut greenhouse gas emissions and reduce fuel costs.

15. How many Tesla Semis will be produced per year?

Elon Musk has set a target of 50,000 Tesla Semis per year once full-scale production is achieved. Initial estimates suggest around 20,000 units could be built in 2026, with volume ramping up afterward.

16. Will the Tesla Semi become fully autonomous in the future?

Yes, Elon Musk has hinted that the Tesla Semi will eventually support unsupervised autonomy, allowing it to operate without a human driver. However, this will depend on regulatory approval and further AI advancements.

Read More:

- “Take Back Tesla:” Unions and corporate watchdogs launch campaign against Musk’s 2025 pay package

- Tesla China’s Megafactory helps boost Shanghai’s battery exports by 20%: report

- Tesla investors want answers to these five questions during Q3 Earnings

- Tesla looks to enter a new continent, new job posting shows

- Tesla’s new Safety Report shows Autopilot is nine times safer than humans

1 thought on “2026 Tesla Semi Truck Mass Production Finally Ready! Elon Musk DROPS AMAZING Upgrade Series”