Tesla Giga Press Machine: Elon Musk, the visionary CEO of Tesla, is known for making bold predictions, but when he said that the Model 2 would become the most mass-produced vehicle ever, with production numbers possibly reaching up to 50 million units, many were skeptical. It sounded like just another one of his grand exaggerations.

However, when Tesla announced the 50,000-ton Giga Press, it became clear that the era of electric vehicle (EV) mass production was about to be revolutionized in a way that had never been seen before.

The 50,000-Ton Giga Press: A Game Changer for EV Manufacturing

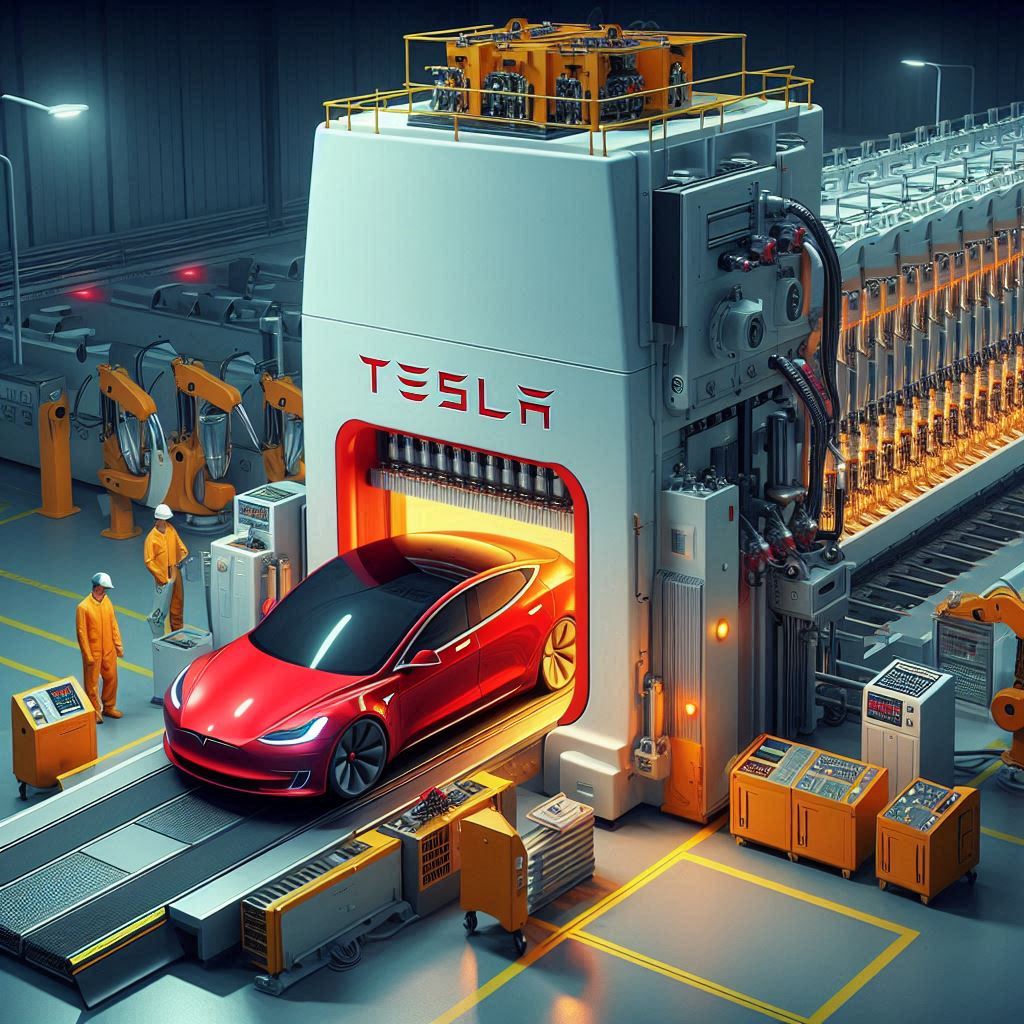

The Giga Press is the cornerstone of Tesla’s plan to produce electric vehicles at unprecedented speeds. This machine is so advanced that it will help Tesla produce up to 5 car bodies simultaneously in a matter of seconds, drastically improving production efficiency. This achievement isn’t just about increasing production speed; it’s about creating a new standard in the automotive industry.

How Does the 50,000-Ton Giga Press Work?

To truly understand the impact of the 50,000-ton Giga Press, we need to dive into how it works. Tesla’s Giga Press operates by using an incredibly powerful casting process that injects molten aluminum into large molds, shaping the vehicle bodies. Here’s a breakdown of the process:

- Material Preparation: Tesla melts down aluminum ingots and leftover material at 850°C.

- Mold Preparation: The molds are coated with a thin layer of oil, which helps in releasing the cast parts later on.

- Injection: The molten aluminum is injected into the mold using high-pressure pistons.

- Cooling: After the casting process, the parts are quickly cooled, solidifying the metal.

- Inspection: Each part undergoes an AI-powered quality control inspection to ensure structural integrity.

Tesla’s goal is to create a car in less than 5 seconds, a feat that has never been achieved in the automotive industry.

The Evolution of Giga Press Machines

Tesla’s Giga Press journey began with smaller machines, but the 50,000-ton version represents a quantum leap in technology. Here’s how Tesla’s Giga Presses have evolved over time:

The 6,000-Ton Giga Press: A Groundbreaking Start

The first step in this innovation was the 6,000-ton Giga Press, introduced in late 2020. It was initially used for the Model Y production, marking the first time a fully cast car frame was produced in a single step. The 6,000-ton press made it possible to reduce the number of parts in the Model Y, lowering the assembly time and cost significantly.

The 9,000-Ton Giga Press: Building the Cybertruck

Next came the 9,000-ton Giga Press, which was used for the production of the highly anticipated Cybertruck. As the demand for EVs grew, Tesla realized that an even more powerful machine was needed to meet their ambitious goals.

The 50,000-Ton Giga Press: The Future of EV Production

Now, Tesla is on the verge of introducing the 50,000-ton Giga Press, the most powerful casting machine in the world. This machine will be able to produce five car bodies at the same time, with an unprecedented production speed. This technology is expected to drastically lower manufacturing costs and improve the quality of Tesla vehicles.

Why the 50,000-Ton Giga Press Will Shake the Industry

Tesla’s move to scale up its production capabilities with the 50,000-ton Giga Press is set to disrupt the entire automotive industry. Here’s why:

Incredible Speed and Efficiency

One of the biggest advantages of the Giga Press is its speed. Tesla’s goal is to produce a single car every 5 seconds, which is a groundbreaking achievement. To put it into perspective, current car manufacturing plants take around 35 seconds to produce a single car, meaning the 50,000-ton Giga Press will be capable of producing seven times as many cars in the same amount of time.

Reducing Costs and Complexity

By reducing the number of parts in a car and simplifying the assembly process, Tesla’s new Giga Press could cut production costs by over 40%. This will make it easier to create affordable vehicles like the Model 2, Tesla’s new compact vehicle.

Enabling the Model 2 Revolution

Tesla’s Model 2 is set to be the most affordable Tesla yet, with a starting price under $30,000. The Model 2 is expected to have a simplified structure with fewer than 80 parts, compared to over 200 parts in the Model Y. This reduced complexity will allow Tesla to produce the Model 2 at massive scale, thanks to the efficiency of the 50,000-ton Giga Press.

A New Manufacturing Philosophy

Elon Musk has often compared the new approach to building cars to assembling toy cars. With Giga Press technology, it’s almost like assembling a giant Lego set, where the car’s frame is produced in one cast. This new method will revolutionize manufacturing, reducing reliance on manual labor and significantly improving safety and precision.

The Impact of the 50,000-Ton Giga Press on Competitors

Tesla’s competitors in the automotive industry will undoubtedly feel the pressure as the 50,000-ton Giga Press enters full-scale production. Here’s why:

Struggles to Keep Up

Most automakers, including Toyota, GM, and Volvo, have yet to even adopt the 6,000-ton Giga Press. While some are beginning to test the waters with smaller machines, Tesla’s massive lead in production technology will be difficult to catch up with. The 50,000-ton press is so advanced that it will likely be years before other manufacturers can replicate the process at scale.

A New Era of Car Production

With the ability to produce five vehicles at once, the 50,000-ton Giga Press will become the industry’s benchmark for high-speed manufacturing. It’s only a matter of time before other automakers are forced to adopt similar technology if they want to stay competitive in the rapidly growing EV market.

What Tesla’s 50,000-Ton Giga Press Means for the Future

Scaling Global Production

Tesla’s focus on mass production, affordability, and speed will allow the company to scale operations globally. With more efficient manufacturing processes, Tesla will be able to produce vehicles at a much lower cost, which will help the company meet the growing demand for electric vehicles worldwide.

Improved Environmental Impact

In addition to being more affordable, Tesla’s focus on speed and efficiency in production also has significant environmental benefits. By reducing waste and improving energy efficiency, the 50,000-ton Giga Press represents a step forward in sustainable manufacturing.

The Bottom Line: A Game-Changer for the EV Industry

In conclusion, Elon Musk’s 50,000-ton Giga Press is set to be the cornerstone of Tesla’s mass production strategy. With the ability to produce five car bodies simultaneously in less than 5 seconds, Tesla is on the verge of revolutionizing the way cars are made. Whether it’s cutting production costs, speeding up the assembly process, or creating affordable vehicles, the 50,000-ton Giga Press is a pivotal piece of Tesla’s master plan to dominate the electric vehicle market.

As other automakers struggle to catch up with Tesla’s technology, the world is about to see a new era in automobile manufacturing. The next few years could bring about massive changes in the way we think about cars, with electric vehicles becoming more affordable and accessible than ever before.

Will Tesla’s Model 2 become the most popular electric car on the market? Will the 50,000-ton Giga Press pave the way for even more innovations in car production? Only time will tell, but one thing is certain: Tesla’s manufacturing revolution is just beginning.

FAQs

1. What is the 50,000-ton Giga Press?

The 50,000-ton Giga Press is an advanced casting machine designed by Tesla to manufacture large sections of electric vehicles, specifically their car bodies. It is capable of producing five car bodies simultaneously in a matter of seconds, significantly improving production speed and efficiency.

2. How does the Giga Press work?

The Giga Press works by injecting molten aluminum into molds under high pressure to create large, single pieces of a car’s frame. This eliminates the need for multiple parts and assembly processes, reducing the overall complexity and cost of production.

3. Why is the 50,000-ton Giga Press important for Tesla?

The 50,000-ton Giga Press is crucial for Tesla because it enables the company to produce cars much faster, reducing the number of parts in a vehicle and lowering production costs. It is also key to the mass production of affordable models like the Model 2, Tesla’s upcoming compact vehicle.

4. What are the advantages of using the Giga Press in manufacturing?

The advantages include:

- Increased production speed, allowing for the creation of a car body in under 5 seconds.

- Lower manufacturing costs due to fewer parts and faster assembly.

- Higher precision and quality, as casting eliminates many human error factors.

- Improved safety and efficiency in the production process.

5. How many cars can the 50,000-ton Giga Press produce at once?

The 50,000-ton Giga Press can produce five car bodies at once, which is a significant improvement over traditional manufacturing methods that take much longer and involve more parts.

6. How does the Giga Press contribute to Tesla’s Model 2?

The Giga Press plays a pivotal role in producing Tesla’s Model 2, the company’s most affordable vehicle. With its ability to quickly produce a simplified vehicle frame, the Giga Press helps keep production costs low, making the Model 2 more affordable for a broader range of consumers.

7. How does the Giga Press compare to previous Tesla Giga Press machines?

Tesla started with a 6,000-ton Giga Press and then moved to a 9,000-ton machine for models like the Cybertruck. The 50,000-ton Giga Press represents a massive leap in scale, offering the ability to produce larger car body parts more quickly and with even more precision than earlier versions.

8. Will other automakers adopt similar technologies to the Giga Press?

Tesla’s competitors may eventually adopt similar casting technologies, but the 50,000-ton Giga Press puts Tesla years ahead of most automakers in terms of production speed and efficiency. While some companies are exploring smaller machines, replicating Tesla’s success with such a large machine will be challenging.

9. How will the 50,000-ton Giga Press affect electric vehicle pricing?

The increased production efficiency from the 50,000-ton Giga Press is expected to lower production costs significantly, allowing Tesla to offer more affordable electric vehicles, such as the Model 2, at lower prices. This could make electric vehicles more accessible to a larger audience and accelerate the transition to electric mobility.

10. When will Tesla start using the 50,000-ton Giga Press in full-scale production?

Tesla has already started testing the 50,000-ton Giga Press, and full-scale production is expected to ramp up over the next few years. As the company refines its technology and builds new production facilities, the Giga Press will play a key role in Tesla’s mass production of affordable EVs.

Read More:

1 thought on “Elon Musk SHOCKED 50,000T Tesla Giga Press Machine Produce 5 NEW Tesla Models”