The Tesla Semi is no longer a futuristic promise or a niche pilot project. It is now entering one of the most critical phases in its history: the transition from limited pilot production to full-scale mass manufacturing. With a new battery technology, a dedicated Semi factory at Giga Nevada, and real-world efficiency data verified by global logistics giants like DHL and ArcBest, Tesla is positioning the Semi Gen 2 as a serious challenger to diesel trucks on both economics and performance.

This article breaks down everything you need to know about the Tesla Semi Gen 2, including its 2026 production schedule, the shift to next-generation 4680 batteries, design and manufacturing upgrades, and real-world efficiency validation that could reshape the heavy-duty trucking industry.

Tesla Semi Enters a New Era of Mass Production

After nearly eight years of development, Tesla is finally ready to scale the Semi in a way that matches the company’s ambitions. The Semi program, first unveiled in 2017, spent years constrained by battery supply, manufacturing bottlenecks, and pilot-scale validation. That era is ending.

Tesla has confirmed that online production of the Tesla Semi will begin in Q1 2026 at a newly built, dedicated Semi factory at Giga Nevada. This is not a symbolic milestone—it represents a full industrial commitment backed by billions in capital investment.

Once fully operational, the Semi facility spans approximately 1.7 million square feet and targets an annualized production rate of 50,000 trucks per year, or just over 4,000 units per month. For the first time, Tesla has aligned factory capacity, battery supply, and customer demand into a single, coherent plan.

Detailed Tesla Semi Production Schedule for 2026

From Pilot Builds to True Volume Production

Tesla’s updated production roadmap for the Semi in 2026 is notably more credible than its earlier timelines. Why? Because this time, it is supported by visible construction progress, installed equipment, and a secured battery supply chain—not just slide decks.

According to Tesla’s Q3 2025 updates:

- Q1 2026: First online builds roll off the Semi production line

- Q2 2026: Controlled production ramp and line debugging

- H2 2026: True volume production targeting 50,000 units annually

This phased approach mirrors how Tesla successfully scaled the Model 3 and Model Y, where early production focused on learning, quality control, and throughput optimization before accelerating output.

The explicit distinction Tesla makes between “online builds” and “real production” signals a more disciplined, automotive-grade industrialization strategy—one that fleet customers can trust.

Giga Nevada: The Backbone of Tesla Semi Scaling

Tesla’s Semi ambitions are anchored by a $3.6 billion investment at Giga Nevada. The site includes:

- A dedicated semi-assembly facility

- A 100 GWh 4680 battery plant

- Integrated logistics and automation infrastructure

The factory is already structurally complete, with equipment installation confirmed as of mid-2025. This marks a dramatic shift from the past, when the Semi relied on shared facilities and limited battery availability.

Crucially, the in-house 4680 battery supply addresses what was previously the program’s single biggest bottleneck. Tesla now controls cell design, manufacturing, and integration—giving it leverage on cost, weight, and scalability.

Regulatory Pressure and Market Demand Align

The timing of Tesla’s Semi ramp is not accidental. Across North America, regulatory pressure is accelerating the shift away from diesel trucks. Policies such as:

- California’s Advanced Clean Trucks (ACT) regulation

- Advanced Clean Fleets (ACF) mandates

are forcing fleets to adopt zero-emission Class 8 vehicles over the next decade.

Major operators including PepsiCo, Walmart, UPS, and Costco have already placed reservations or signaled strong interest. These companies face both compliance requirements and corporate decarbonization targets, creating structural demand for electric trucks that can operate at scale.

Battery Evolution: From LFP to 4680 Cells

Why the Battery Strategy Matters

Tesla’s battery roadmap for the Semi is central to its credibility. From 2022 to 2025, the Semi effectively functioned as a low-volume experimental platform, using multiple chemistries:

- LFP (Lithium Iron Phosphate) packs (~500 kWh) for 300-mile variants

- Nickel-based chemistries (NCA/NCM) (~800–900 kWh) for 500-mile variants

This dual approach allowed Tesla to validate real-world duty cycles, degradation behavior, and cost-performance tradeoffs.

The 4680 Breakthrough

For 2026, Tesla is standardizing the Semi Gen 2 on a high-voltage 4680 battery architecture. This is not a minor update—it fundamentally changes the economics and physics of the truck.

According to Tesla:

- Over 7% efficiency improvement

- Up to 20% reduction in battery weight

- Same 500-mile range with less total energy

Higher gravimetric and volumetric energy density means Tesla can reduce pack size while maintaining range. In practical terms, this could remove hundreds of kilograms (over 1,000 lbs) from the battery system.

Weight Reduction = More Payload, More Profit

Tesla is targeting a tractor curb weight below 23,000 lbs, compared to earlier estimates of 24,000–26,000 lbs for Gen 1 trucks.

For fleet operators bound by the 80,000 lb gross vehicle weight limit, every pound removed from the tractor is a pound that can be added to payload. That directly increases revenue per trip.

This weight reduction is achieved through:

- Structural integration of the 4680 pack

- Use of high-strength steels and alloys

- Modular underbody design optimized for automation

- Tesla’s signature manufacturing techniques like gigacastings

Tesla Semi Gen 2 Design and Manufacturing Upgrades

Designed for Scale, Not Just Performance

The Semi Gen 2 represents a shift from engineering prototype to a platform optimized for high-volume manufacturing and long service life.

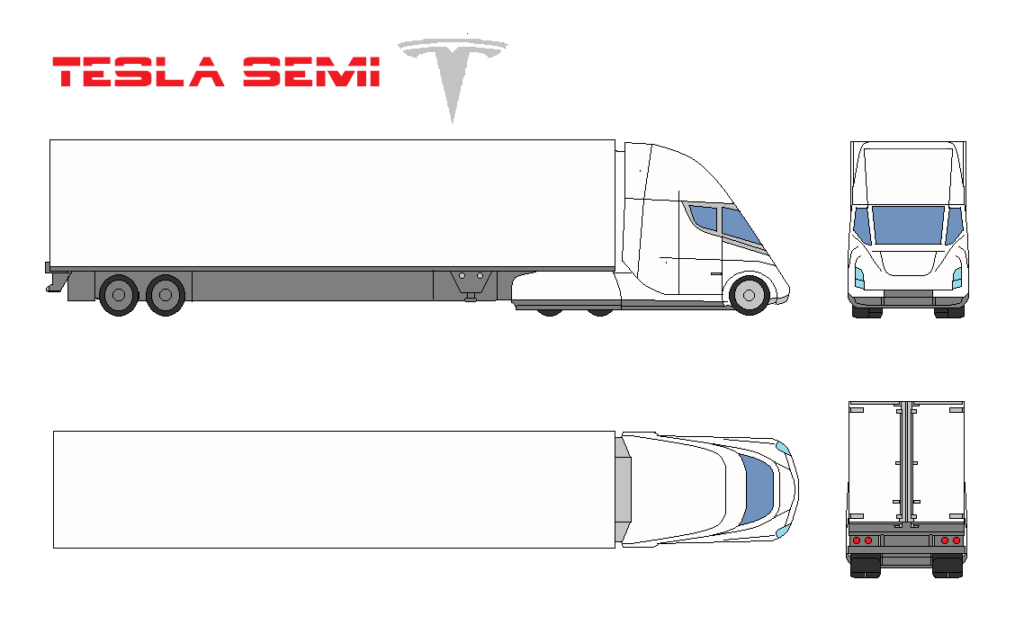

Exterior and Aerodynamics

- LED headlamps shared with Model Y and Cybertruck

- Smaller, more steeply raked windshield

- Softer, more conventional roofline

- Improved airflow and reduced drag

These changes are not cosmetic. They reduce tooling costs, simplify supply chains, and improve real-world efficiency over millions of fleet miles.

Gigapress Comes to the Tesla Semi

For the first time, Tesla is deploying its Gigapress technology on the Semi production line. This allows large chassis components to be cast in minutes instead of hours, dramatically reducing part count and assembly complexity.

The goal? One truck every few minutes once the factory reaches steady-state production.

Autonomy-Ready by Design

One of the most important Gen 2 upgrades is the Semi’s autonomy architecture.

- 26+ cameras for full 360° coverage

- Redundant visibility around blind spots and trailer edges

- Centralized compute architecture with fewer ECUs

- Over-the-air update capability

By designing the truck around autonomy hardware from day one, Tesla avoids the compromises of retrofitting. This future-proofs the Semi for advanced driver assistance today and higher levels of automation tomorrow.

Electric Power Takeoff (ePTO): A Game-Changer

The Semi Gen 2 introduces an electric power takeoff system (up to ~25 kW). This allows the truck to power:

- Refrigerated trailers

- Hydraulic pumps

- Auxiliary equipment

All without a separate diesel engine.

This eliminates idling emissions, reduces noise, cuts maintenance costs, and helps fleets comply with anti-idling regulations—especially in ports and urban logistics hubs.

Real-World Efficiency: Verified by DHL, PepsiCo, and ArcBest

PepsiCo: Millions of Miles of Proof

Tesla’s launch partner, PepsiCo, has logged over 7.5 million kilometers since 2022. Reported energy consumption often beats Tesla’s 1.7 kWh/mile target, even under loaded conditions.

Pepsi has also demonstrated 24-hour duty cycles using Tesla’s Megacharger network, proving the Semi can support high-utilization freight operations.

DHL: Heavy Loads, Real Results

After trials, DHL took delivery of its first Tesla Semi in December 2025 and reported:

- ~1.72 kWh per mile

- 75,000 lb gross vehicle weight

DHL estimates ~50 metric tons of CO₂ emissions avoided per truck per year, a material impact for a global logistics provider.

ArcBest: Even Better Than Expected

ArcBest’s three-week trial in mid-2025 delivered one of the most impressive results yet:

- 1.55 kWh per mile over 4,494 miles

Drivers also praised visibility, comfort, and ease of operation—critical factors in an industry struggling with driver retention.

The Economics: Electric vs Diesel

While Tesla Semi pricing has risen from the originally announced $180,000, industry estimates now place real transaction prices between $250,000 and $400,000, depending on configuration.

Despite higher upfront costs, operating economics strongly favor electric:

- Tesla Semi:

- ~1.7 kWh/mile

- ~$0.20/kWh industrial electricity

- ~$0.34 per mile

- Diesel Truck:

- ~7 mpg

- ~$4.50/gallon

- ~$0.64 per mile

That’s a $0.30 per mile savings, translating to ~$30,000 per year at 100,000 miles—before maintenance savings.

Final Thoughts: Is Tesla Ready to Disrupt Heavy-Duty Trucking?

With the 4680 battery transition, Gigapress manufacturing, verified real-world efficiency, and a clear 2026 production roadmap, the Tesla Semi Gen 2 is no longer a speculative concept. It is shaping up to be a commercially viable, scalable alternative to diesel.

The remaining questions revolve around long-term battery durability, replacement costs, and final pricing stability—but the data so far suggests Tesla has solved many of the core challenges that once held electric Class 8 trucks back.

As mass production begins and fleets scale deployments, 2026 could mark the moment when electric trucking moves from pilot programs to industry standard.

What do you think? Has Tesla’s shift to 4680 batteries truly solved the cost and weight problem—or does it introduce new risks?

FAQs

1. What is the Tesla Semi Gen 2?

The Tesla Semi Gen 2 is the latest evolution of Tesla’s all-electric Class 8 truck, featuring next-generation 4680 battery cells, improved efficiency, reduced weight, and a design optimized for mass production and long-haul freight operations.

2. When will Tesla Semi Gen 2 enter mass production?

Tesla plans to begin online production in Q1 2026, followed by a controlled ramp in Q2 and full-scale volume production in the second half of 2026, targeting 50,000 units per year.

3. Where is the Tesla Semi being manufactured?

The Tesla Semi is being built at a dedicated 1.7 million square foot facility at Giga Nevada, supported by a 100 GWh 4680 battery plant to secure battery supply.

4. What battery does the Tesla Semi Gen 2 use?

The Gen 2 Tesla Semi uses high-voltage 4680 battery cells, replacing earlier LFP and nickel-based chemistries used in pilot production trucks.

5. How much range does the Tesla Semi Gen 2 offer?

Despite using less total battery energy, the Tesla Semi Gen 2 maintains a 500-mile range, thanks to efficiency improvements of over 7%.

6. How efficient is the Tesla Semi in real-world driving?

Real-world trials show energy consumption between 1.55 and 1.72 kWh per mile, confirmed by partners like PepsiCo, DHL, and ArcBest, even under heavy loads.

7. How much does the Tesla Semi Gen 2 weigh?

Tesla is targeting a tractor curb weight below 23,000 lbs, a significant reduction compared to earlier estimates of 24,000–26,000 lbs.

8. Why is lower weight important for fleet operators?

Lower tractor weight allows fleets to carry more payload within the 80,000 lb gross vehicle weight limit, directly increasing revenue per trip.

9. What is the Gigapress and why is it important for the Semi?

The Gigapress is Tesla’s large-scale casting technology that produces major chassis components in minutes, reducing part count, cost, and assembly time, enabling one truck to roll off the line every few minutes.

10. Does the Tesla Semi Gen 2 support autonomous driving?

Yes. The Semi Gen 2 is autonomy-ready, featuring 26+ cameras, centralized computing, and hardware designed to support advanced driver assistance today and higher autonomy levels in the future.

11. What is the electric power takeoff (ePTO) system?

The ePTO system allows the Tesla Semi to power refrigerated trailers and auxiliary equipment directly from its battery, eliminating the need for diesel-powered auxiliary engines.

12. How much does it cost to operate a Tesla Semi compared to diesel?

At around $0.34 per mile in energy costs, the Tesla Semi is significantly cheaper to operate than a diesel truck, which averages ~$0.64 per mile, saving fleets about $30,000 per year per truck.

13. What is the expected price of the Tesla Semi Gen 2?

While Tesla originally announced a $180,000 price, industry estimates suggest current prices range from $250,000 to $400,000, depending on configuration and battery size.

14. Which companies are currently using the Tesla Semi?

Early and current users include PepsiCo, DHL, ArcBest, with reported interest or upcoming deployments from Walmart, Costco, UPS, and Cisco.

15. How does the Tesla Semi help reduce emissions?

Each Tesla Semi can reduce around 50 metric tons of CO₂ emissions per year compared to a modern diesel truck, helping fleets meet sustainability and regulatory goals.

16. Can the Tesla Semi handle long-haul and high-utilization routes?

Yes. Demonstrations have shown the Semi completing 24-hour duty cycles using Tesla’s Megacharger network, proving it can support long-haul and regional freight operations.

17. Is the Tesla Semi Gen 2 a real threat to diesel trucks?

Yes. With verified real-world efficiency, lower operating costs, regulatory tailwinds, and scalable production planned for 2026, the Tesla Semi Gen 2 is emerging as a serious competitor to traditional diesel Class 8 trucks.

Read More:

- Tesla analyst teases self-driving dominance in new note: ‘It’s not even close’

- Tesla Cybercab ‘breakdown’ image likely is not what it seems

- Elon Musk Announces 2026 Tesla Motorhome For Under $9,999

- Tesla is coming to Estonia and Latvia in latest European expansion: report

- Tesla seeks engineer to make its iOS Robotaxi app feel “magical”

1 thought on “Tesla Semi Gen 2 New Battery Spotted at Giga Nevada! Elon Musk Reveals BIG Plan with DHL”