The electric vehicle industry has learned to be cautious. Over the last decade, we’ve seen countless battery “breakthroughs” grab headlines, only to quietly fade when real-world engineering challenges set in. That’s why this latest claim is different. It didn’t come from a flashy press release or a hype-driven startup pitch. It came after Sandy Munro, one of the most respected manufacturing and engineering analysts in the automotive world, personally inspected the technology inside a factory and walked away impressed.

When someone with Munro’s track record pauses and says, “This deserves attention,” the EV community listens.

At the center of this discussion is a new semi-solid lithium-ion battery technology developed by 24M, a Massachusetts-based company. The numbers alone are eye-catching: up to 660 watt-hours per kilogram, 200 miles of range added in about four minutes, strong cold-weather performance, and a theoretical path to 1,000 miles of driving range on a single charge. But as any seasoned EV watcher knows, numbers don’t matter unless they survive manufacturing, durability testing, and real-world use.

This article breaks down what this battery actually is, why engineers are paying attention, how it compares to today’s EV batteries, and whether it has a realistic path to powering future electric vehicles.

Why Battery Breakthrough Claims Deserve Skepticism

Every few months, headlines promise the battery that will “change everything.” Yet today’s production EVs still rely largely on conventional lithium-ion technology with pack-level energy densities far below the most ambitious lab claims.

The biggest red flags usually include:

- Measurements taken only at the cell level, not the full battery pack

- Unproven cycle life, especially under fast charging

- Poor performance in extreme cold or heat

- Manufacturing processes that don’t scale economically

That’s why the key questions matter:

- Are the claimed figures measured at the cell level or pack level?

- How many charge cycles can the battery realistically endure?

- After 500 cycles, how much capacity remains?

- Does ultra-fast charging destroy long-term durability?

Without clear answers, even impressive numbers risk being little more than marketing.

Meet 24M: A Different Kind of Battery Company

24M, short for 24M Technologies, is based in Cambridge, Massachusetts, and its approach stands out because it avoids chasing science-fiction promises. This is not a solid-state battery, a technology that has been discussed for years but still struggles with cost, manufacturability, and reliability at scale.

Instead, 24M focuses on fixing the real problems of today’s lithium-ion batteries:

- High manufacturing cost

- Safety risks from complex layered designs

- Limited energy density

- Difficult recycling and high environmental impact

Their solution is a semi-solid lithium-ion battery design, paired with a radically simplified manufacturing process.

What Makes 24M’s Semi-Solid Battery Different

The Problem with Traditional Lithium-Ion Batteries

Conventional lithium-ion cells rely on:

- Thin, dry electrode sheets

- Complex rolling and stacking

- Extremely tight manufacturing tolerances

Even small defects can cause internal shorts, dendrite growth, and long-term degradation. The process is expensive, energy-intensive, and difficult to scale without massive capital investment.

24M’s Semi-Solid Manufacturing Breakthrough

24M replaces those delicate steps with its proprietary semi-solid manufacturing process. Instead of pressing dry powders into thin layers, the company:

- Mixes the electrolyte directly with active materials

- Creates a thick slurry

- Deposits it directly onto metal foils

This single change eliminates around 50% of traditional manufacturing steps.

Practical benefits include:

- Lower factory energy use

- Reduced capital cost

- Thicker electrodes

- Improved safety margins

- Higher energy density

In short, the battery becomes easier to build, cheaper to produce, and more tolerant of real-world manufacturing variation.

The 660 Wh/kg Energy Density Explained

Energy density is the holy grail of EV batteries. Today’s production EVs typically achieve pack-level energy densities between 150 and 250 Wh/kg, while cutting-edge cells may approach 350–400 Wh/kg in controlled environments.

24M claims up to 660 Wh/kg at the cell level.

Why That Number Matters

- 400 Wh/kg is often cited as the threshold for demanding applications like high-performance EVs and aerospace

- 660 Wh/kg opens the door to dramatically lighter battery packs

- Lighter batteries mean longer range, better efficiency, and lower system weight

If even a portion of that performance carries over to the pack level, it could fundamentally change EV design.

1,000 Miles of Range: Fantasy or Feasible?

A 1,000-mile EV sounds absurd—until you look at the math.

In China, manufacturers have already demonstrated ~1,000 miles of range using ~500 Wh/kg cells in controlled configurations. That puts 24M’s claims firmly within the realm of engineering plausibility, not science fiction.

For drivers, this would:

- Surpass the 400–600 mile range of most gasoline cars

- Eliminate range anxiety entirely

- Turn EVs into true road-trip vehicles

At that point, charging convenience becomes more important than total range—and that’s where fast charging enters the picture.

4-Minute Charging: Game-Changer or Gimmick?

24M reports charging capability equivalent to 200 miles of range in about four minutes.

Why This Is Different

- Does not require megawatt chargers

- Designed to work with existing 400V and 800V fast-charging systems

- Uses current more efficiently than many existing EV platforms

This matters because infrastructure upgrades are one of the biggest barriers to widespread EV adoption. A battery that delivers ultra-fast charging without new charging hardware changes the economics entirely.

Cold Weather Performance: The Silent EV Killer

Cold temperatures remain one of the biggest pain points for EV owners. Range drops, charging slows, and battery degradation accelerates.

24M claims:

- Stable performance at extreme cold temperatures

- Strong low-temperature charging behavior

- Improved electrolyte behavior compared to conventional designs

If validated, this could make EVs far more practical in northern climates where adoption has lagged.

Why This Isn’t a Solid-State Battery—and Why That’s Good

Solid-state batteries promise safety and energy density but struggle with:

- Cracking at material interfaces

- Difficult large-scale manufacturing

- High costs

24M’s semi-solid approach keeps the benefits of liquid electrolytes while dramatically simplifying production. It’s a pragmatic engineering solution, not a moonshot.

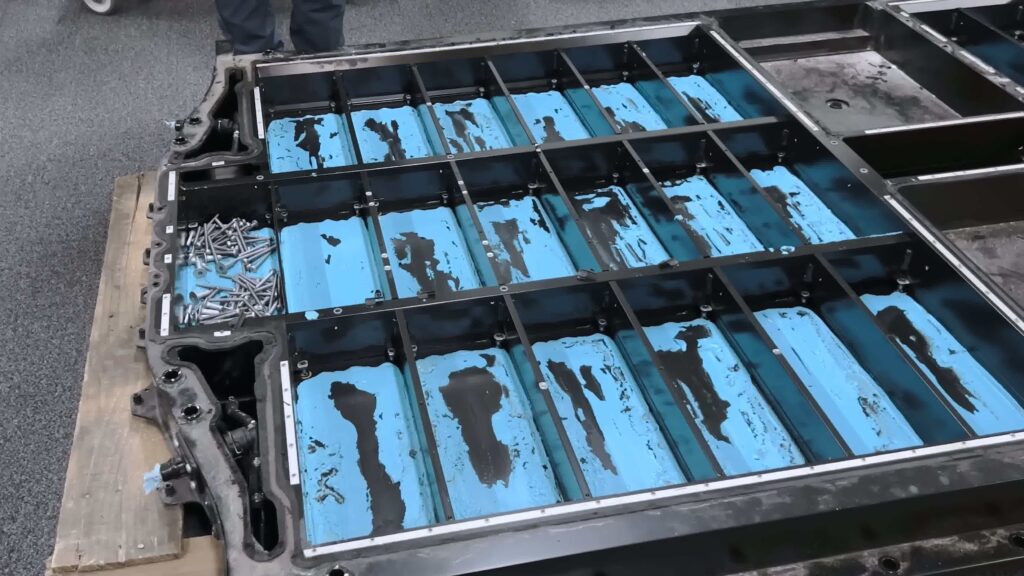

Electrode-to-Pack (ETOP): Rethinking the Battery Pack

Beyond chemistry, 24M is attacking another major inefficiency: battery packaging.

Traditional EV batteries follow a cell → module → pack structure. Each layer adds:

- Weight

- Cost

- Inactive material

ETOP Changes the Game

24M’s Electrode-to-Pack (ETOP) architecture:

- Collapses multiple layers of packaging

- Allows electrodes to occupy up to 80% of pack volume

- Compared to 30–60% in conventional designs

This increases packaging efficiency to around 80%, versus roughly 60% or less today.

Why That Matters

- Less metal casing

- Fewer duplicated structures

- More of what you pay for is actual energy storage

Industry reports suggest up to 40% cost reduction at the pack level if these efficiencies scale.

Cost: Could This Battery Be Cheaper Than Today’s?

Battery cost isn’t just about materials. It’s driven by:

- Manufacturing complexity

- Capital equipment

- Energy use

- Yield rates

24M claims:

- 50% fewer manufacturing steps

- Over 50% reduction in capital cost

- Lower energy consumption per kWh

If validated, this creates a credible path to lower-cost EV batteries, not just better ones.

Real-World Scaling: Where Is 24M Today?

This is no longer a lab experiment.

Key milestones include:

- Volkswagen partnership announced in 2021

- Licensed manufacturing partners scaling semi-solid production

- Expansion toward commercial-scale energy storage by FY2026

- Pilot-scale production already underway in the United States

Automotive qualification is slow by necessity. Expect:

- Late 2020s for early vehicle deployment

- Pilot or fleet applications first

- Gradual consumer rollout after validation

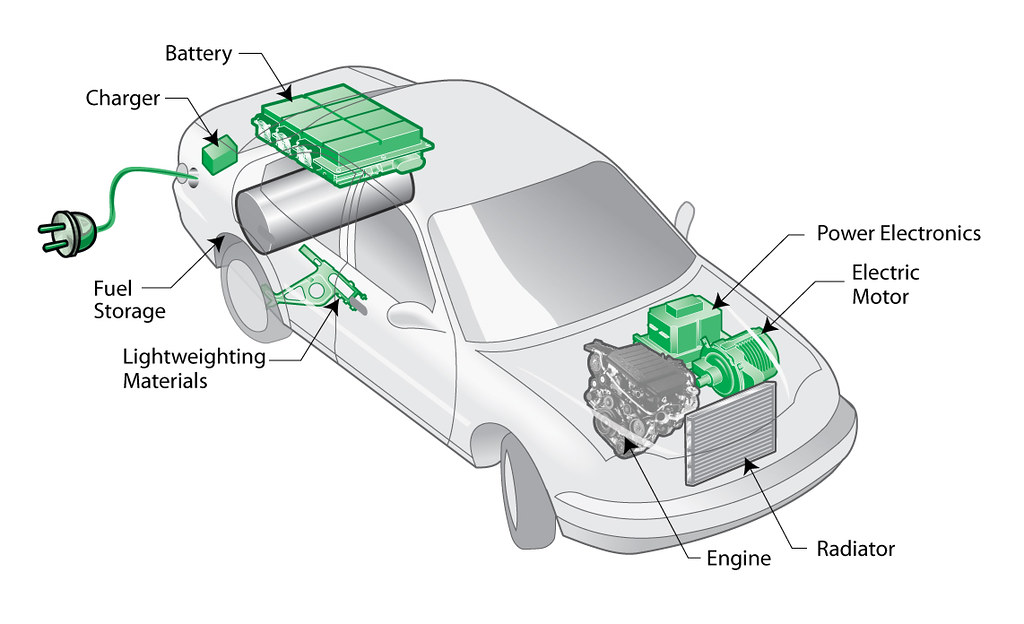

The Lithium Supply Puzzle and Tesla’s Role

Battery breakthroughs mean nothing without raw materials.

In January 2026, Tesla brought its lithium refinery in Corpus Christi, Texas, online, the largest of its kind in North America.

Why This Matters

- Produces battery-grade lithium hydroxide

- Supports ~1 million EVs per year

- Uses a cleaner, acid-free process

- Reduces reliance on foreign lithium refining

This upstream investment complements downstream innovations like 24M’s battery technology, strengthening the domestic EV supply chain.

Are the Claims Guaranteed? No—and That’s the Point

Batteries don’t fail in presentations. They fail in:

- Winter mornings

- Summer heat

- Fast-charge cycles

- Vibration tests

- Warranty data

The smartest way to view 24M’s claims is as targets under validation, not promises carved in stone.

What is compelling is the structural logic:

- Fewer steps

- Lower capex

- Higher packaging efficiency

- More manufacturable designs

Historically, those factors are what turn good ideas into real products.

Final Verdict: Hype or Historic Shift?

24M’s battery technology looks commercially plausible, cost plausible, and engineering plausible because it attacks the factory and the pack—not just the chemistry.

If the performance holds up:

- EVs could achieve longer range without bigger batteries

- Fast charging could feel gasoline-like

- Costs could fall instead of rise

Expect limited deployments before mass adoption, and watch for early wins in either cheaper packs at the same range or dramatically longer range at the same size.

The real question now isn’t if EVs can reach this level—it’s how fast the industry can validate and scale what finally looks like a practical breakthrough.

If ultra-fast charging really delivers convenience without sacrificing durability, this could be the moment when EVs stop feeling like a compromise and start feeling like the obvious choice.

FAQs

1. What is the world’s first EV battery claiming 1,000 miles of range?

The battery is a semi-solid lithium-ion battery developed by 24M Technologies. It claims up to 660 Wh/kg energy density at the cell level, which could theoretically enable around 1,000 miles of driving range in a vehicle designed around it.

2. Is this a solid-state battery?

No. This is not a solid-state battery. It uses a semi-solid lithium-ion design, which keeps some liquid electrolyte while simplifying manufacturing and improving scalability compared to solid-state concepts.

3. What does 660 Wh/kg actually mean?

660 watt-hours per kilogram (Wh/kg) measures how much energy a battery can store relative to its weight. This is far higher than today’s commercial EV batteries, which typically range between 250–400 Wh/kg at the cell level.

4. Are these energy density numbers measured at the cell or pack level?

The 660 Wh/kg figure is reported at the cell level. Final pack-level energy density will be lower, but even partial retention of this performance could significantly improve EV range.

5. Can this battery really charge 200 miles in 4 minutes?

According to 24M, yes—under optimal conditions. The technology is designed to deliver ultra-fast charging using existing 400V and 800V fast-charging systems, not specialized megawatt chargers.

6. Does ultra-fast charging damage the battery faster?

That’s one of the key questions still under validation. Fast charging traditionally accelerates degradation, but 24M claims its chemistry and design improve durability. Long-term real-world data is still needed.

7. How many charge cycles can this battery last?

24M has not yet published full automotive-grade cycle-life data. Cycle life under fast charging and extreme temperatures remains one of the most important hurdles before mass-market adoption.

8. How does this battery perform in cold weather?

The company reports stable performance at very low temperatures, potentially down to -40°C, addressing one of the biggest weaknesses of conventional EV batteries.

9. Why is Sandy Munro’s involvement important?

Sandy Munro is a highly respected automotive manufacturing expert. His personal inspection and public praise signal that this technology has real engineering merit, not just marketing hype.

10. What makes 24M’s manufacturing process different?

24M replaces traditional dry electrode layering with a semi-solid slurry process, cutting about 50% of manufacturing steps, reducing energy use, and lowering factory costs.

11. What is ETOP (Electrode-to-Pack) technology?

ETOP integrates electrodes more directly into the battery pack, eliminating traditional cell and module layers. This allows up to 80% of the pack volume to be active material, compared to 30–60% today.

12. Will this battery be cheaper than current EV batteries?

Potentially yes at the pack level. By reducing manufacturing steps, factory capex, and inactive materials, cost reductions of up to 40% have been claimed, pending large-scale validation.

13. When could this battery appear in real electric vehicles?

The most realistic timeline is late 2020s for early production vehicles, with pilot or fleet deployments possibly earlier if automakers commit.

14. Is this battery already being produced in the U.S.?

Yes. Pilot-scale production is already underway in the United States, marking a major step beyond laboratory prototypes.

15. Which automakers are interested in 24M’s technology?

Volkswagen publicly announced a strategic partnership with 24M to industrialize its semi-solid battery technology. Other OEM interest has been reported through licensing partnerships.

16. How does Tesla’s lithium refinery connect to this battery breakthrough?

Tesla’s Texas lithium refinery provides domestic battery-grade lithium hydroxide, a critical raw material. This strengthens the supply chain needed for next-generation batteries like 24M’s.

17. Does this battery reduce reliance on China’s battery supply chain?

It helps, but doesn’t eliminate dependence entirely. Domestic manufacturing and refining are growing, yet China still dominates global lithium processing and battery production.

18. Is this battery a guaranteed breakthrough or still a risk?

It is promising but not guaranteed. The technology is structurally and economically plausible, but long-term durability, automotive validation, and large-scale manufacturing consistency must still be proven.

Read More:

- SpaceX strengthens manufacturing base with Hexagon Purus aerospace deal

- Tesla tops France reliability rankings, beating Toyota for the first time

- Elon Musk confirms Tesla Semi will enter high-volume production this year

- Elon Musk pivots SpaceX plans to Moon base before Mars

- Ferrari Luce EV: Italian supercar maker reveals interior and interface design