The idea of building a house without bricks, without mortar, and even without an architect used to sound like pure science fiction. But Elon Musk and Tesla are pushing this once-impossible dream into reality through a robot-driven, factory-assembled tiny home that costs just $7,899—including a steel frame, insulation, interior modules, and even a full energy system ready to plug in.

Instead of the traditional construction mess filled with dust, scaffolding, and laborers, Tesla wants your home to be manufactured like a car. Inside a Gigafactory, robots weld the frame, stamping lines shape insulated wall and roof panels, and pre-built living pods slide into place like Lego blocks. The result? A home that arrives on a truck, and you can move in the same day.

This blog breaks down the exact five production stations that make the Tesla Tiny House possible—and reveals how Tesla uses the same production lines that build more than 1.77 million vehicles per year to drastically reduce the cost of housing.

Tesla’s Revolutionary Approach to Housing

Traditional construction is slow, expensive, messy, and prone to errors. Tesla is replacing this with a highly controlled, fast, automated manufacturing environment. Instead of building a house, Tesla assembles one.

The key ingredients?

- Robotic welding systems

- High-precision steel stamping machines

- Pre-fabricated living pods

- Integrated Tesla Energy system

- Factory-level quality control and stress testing

And all of it comes together in just five stations.

Station 1 – Frame and Floor: The Steel Skeleton

Every Tesla Tiny House begins with one requirement:

make the frame and floor perfectly accurate.

If the floor is uneven or the frame is misaligned, everything else that follows—walls, doors, living pods—will be compromised. That’s why Station 1 uses the same body-shop technology that Tesla uses for vehicles.

Borrowing From Tesla’s Automotive Expertise

In 2024, Tesla produced roughly 1.77 million vehicles, meaning its factories are already building about 4,850 frames every day. This experience makes transitioning to tiny house frames extremely efficient.

Robotic Frame Welding

At Station 1:

- Steel beams are placed on a conveyor.

- Robots weld each beam with millimeter-level precision.

- Load-bearing zones (kitchen, bathroom, energy unit) get extra reinforcement.

- Laser scanners analyze the final geometry and correct deviations.

This ensures every tiny house frame is identical, meaning the rest of the home snaps together with minimal human effort.

Pre-Stamped Mounting Points: The Secret Weapon

Tesla integrates pre-stamped mounting holes throughout the frame. These slots allow:

- Wall panels

- Roof panels

- Kitchen pod

- Bathroom pod

- Sleeping pod

- Energy core

…to attach instantly.

This transforms the process from construction to rapid assembly, much like building a Tesla vehicle.

Production Capacity Potential

With Tesla already capable of producing 1.77 million frames per year, dedicating just 5–10% of that capacity could allow for:

- 90,000 to 180,000 tiny houses annually

This means Tesla’s tiny house project isn’t a “small experiment”—it’s capable of disrupting the housing market at scale.

Station 2 – Smart Shell: High-Precision Walls & Roof Panels

Once the steel skeleton is complete, Station 2 gives it a fully insulated, high-strength shell.

Tesla uses the same coil-fed steel stamping lines used to shape Model Y body panels. These monsters can apply:

- 7,300 tons of force

- Up to 16 panels per minute

What Makes Tesla’s Wall Panels Smart?

Tesla’s wall and roof panels come pre-built with:

- Insulation core

- Window & door openings

- Pre-set electrical channels

- Sound and heat resistance

- Edge connectors for “plug-and-play” wiring

No bricks.

No mortar.

No rewiring walls on site.

Built for Fast Assembly

Workers simply:

- Lift the panels.

- Align them with the pre-stamped holes on the frame.

- Secure them with bolts.

- Connect the electrical plugs.

What normally takes weeks on a construction site now takes hours.

Gigafactory-Level Output

If a reconfigured stamping line produces around:

- 6,000 panels per day

- 10–12 panels per tiny house

That equals up to 500 tiny house shells daily.

This confirms Tesla isn’t just building homes—it’s mass-manufacturing them.

Station 3 – Living Pods: Kitchen, Bathroom & Bedroom Modules

Here is where Tesla shifts from construction to modular manufacturing.

Your Tesla home includes three plug-and-play living pods:

- Bathroom Pod

- Kitchen Pod

- Sleeping Pod

Each is fully assembled and tested before ever entering the house.

Bathroom Pod – The Most Complex Module

The bathroom includes:

- Toilet

- Shower

- Sink

- Water system

- Drainage

- Exhaust fan

- Compact technical box

It undergoes:

- Pressure tests

- Continuous water spray tests

- Drainage flow tests

Studies show prefabricated bathrooms reduce onsite labor by ~50%, meaning your bathroom arrives perfect and leak-free.

Kitchen Pod – Efficient and Fully Wired

The kitchen pod includes:

- Cabinets

- Sink

- Induction cooktop

- Outlets

- Lighting

- Structured wiring harness

Technicians test:

- Cooktop load

- Voltage and temperature stability

- Drainage performance

All errors are fixed in the factory—not in your backyard.

Sleeping Pod – Comfort on Rails

This pod includes:

- Bed

- Wardrobe

- Shelves

- Lighting

- Outlets

It aligns perfectly with the frame’s load points and connects via quick electrical connectors.

Unboxed Manufacturing (Tesla’s Unique Advantage)

Tesla builds pods in parallel—not inline.

This increases production speed by 30% and saves 40% factory space.

Final Pod Installation

Pods are slid into the frame using forklifts or rail systems.

Connections include:

- Quick-connect electrical links

- Bolt-on mechanical joints

- Lock-in water lines

Everything is installed within 1–2 working days, saving weeks of labor.

Station 4 – Energy Core: The Heart of the Tesla Tiny House

You can’t live in a house without power. That’s why Station 4 installs a complete, ready-to-use Tesla Energy Core.

Tesla’s Massive Energy Manufacturing Power

In 2024, Tesla deployed:

- 31.4 GWh of energy storage

- Up to 10,000 Megapack units/year

- More than 750,000 Powerwalls installed globally

If each Tesla Tiny House uses:

- 10–15 kWh

Tesla’s existing production capacity could power millions of tiny homes.

What’s Inside the Energy Core?

The Energy Core includes:

- A Powerwall-based battery pack

- A bi-directional inverter

- A complete electrical distribution panel

All pre-installed.

All pre-tested.

All ready to use.

Factory-Tested Reliability

Before shipping, the core undergoes:

- High-voltage system tests

- Insulation resistance checks

- Load simulation

- Outage transition tests

This gives the tiny house the same durability as a Powerwall—

10-year warranty, 70% minimum capacity guarantee.

Plug-In Installation

Thanks to the integrated design:

- No electricians required

- No 4–6 hour power shutdown

- No on-site wiring

The Energy Core bolts in and powers up in mere hours.

Station 5 – Stress Test & Seal: Ready for Real Life

Before leaving the factory, each Tesla Tiny House undergoes a full stress-testing cycle similar to vehicle quality checks.

Rain Test (Japanese Industrial Standard D0203)

The house is blasted with:

- 24.5–39.2 L/min of water

- For 30–60 minutes

An engineer inside checks for leaks.

If anything leaks, the house is resealed and retested.

Your home survives a simulated storm before ever facing real weather.

Vibration Test

The house sits on a multi-axis shaker:

- 1–40 Hz frequencies

- 0.3–0.5 g acceleration

- For up to one hour

Sensors detect:

- Loose bolts

- Panel gaps

- Structural movement

Anything out of tolerance is fixed immediately.

Electrical Load Test

Technicians load the electrical system at 80–100% capacity for several hours.

They test:

- Connector temperature rise (<30K)

- Voltage drop

- Inverter behavior

- Battery performance

This ensures no electrical surprises when you plug in your appliances.

Ventilation & Airtightness Test

Engineers measure:

- Air changes per hour (target 3–6)

- Pressure difference (30–50 Pa)

- Shell leakage levels

You get a home that’s efficient but not so airtight it traps moisture.

Why These Tests Matter

Poor quality can consume:

- 10–20% of revenue

- 70–80% of total quality cost

Tesla performs these tests to guarantee that your home is:

- Safe

- Dry

- Quiet

- Structurally sound

- Move-in ready

- Rent-ready

Right from day one.

How Tesla Turns a $7,899 Tiny House Into a Mass-Production Miracle

Here’s the summary of why Tesla can build such an affordable, high-quality home:

- Reuses automotive manufacturing systems

- Automates 70%+ of assembly

- Builds living pods in parallel

- Uses mass-production stamping lines

- Integrates Tesla Energy systems

- Completes homes in days—not months

- Runs full stress-testing before delivery

This is not “cheap housing.”

This is automotive-level precision and durability applied to living spaces.

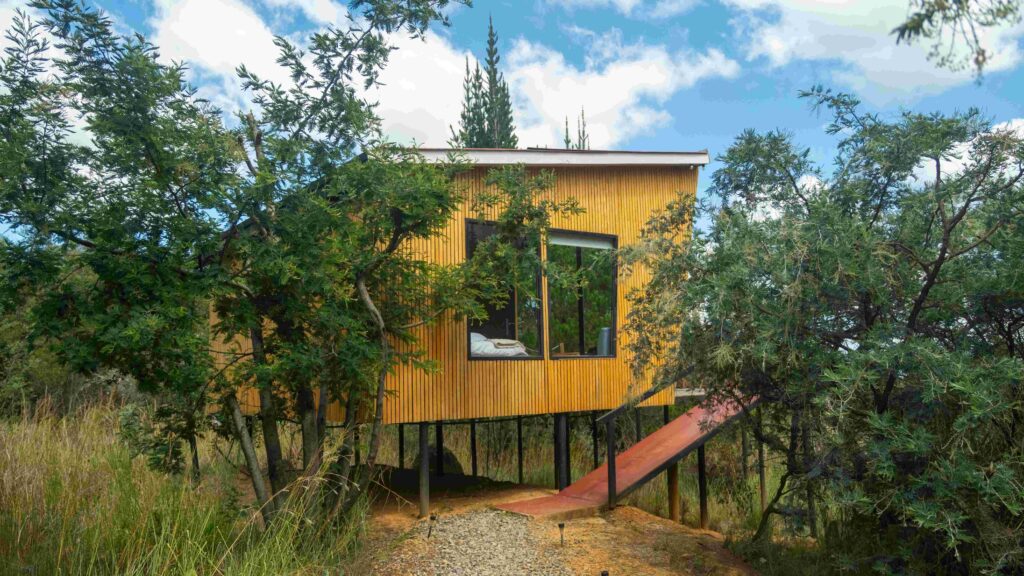

Why the Tesla Tiny House Changes Everything

This $7,899 home could disrupt:

- Low-cost housing

- Student housing

- Disaster relief

- Airbnb & vacation rentals

- Off-grid living

- Backyard ADUs

- Workforce housing

- Sustainable eco-living

With production capacity potentially exceeding 180,000 units/year, Tesla could become one of the largest home manufacturers in the world—without ever building a traditional construction site.

Conclusion: A Factory-Built Home Ready to Deliver

Tesla has taken everything it learned from producing millions of cars and billions of watt-hours of energy storage and applied it to housing.

From:

- robotic frame welding

- precision wall stamping

- prefab living pods

- plug-and-play energy systems

- automotive-grade stress testing

…the result is a tiny home that is affordable, durable, move-in ready, and built at industrial scale.

The Tesla Tiny House is no longer an idea.

It’s a product—and it’s here.

FAQs

1. How much does the Tesla Tiny House actually cost?

The base price is $7,899, which includes the steel frame, insulated shell, living pods, and a complete Tesla Energy Core.

2. Is $7,899 the final price or are there extra fees?

The price covers manufacturing, but you may still need to pay for delivery, land, permits, and site preparation, depending on your location.

3. How long does it take to build a Tesla Tiny House?

Because it is factory-assembled, each unit can be completed in 1–2 days on the assembly line plus a few hours for final energy integration.

4. Can you move into the Tesla Tiny House the same day it arrives?

Yes. The home arrives fully tested and ready to use, including electrical and interior modules.

5. What is the size of the Tesla Tiny House?

While Tesla has not released final square footage, early prototype specs suggest 100–200 sq ft, depending on configuration.

6. Does the home come with a bathroom and kitchen?

Yes. Both the Bathroom Pod and Kitchen Pod come fully prebuilt with plumbing, wiring, cabinets, fixtures, and ventilation.

7. Does the Tesla Tiny House include electricity and a battery system?

Yes. The Energy Core is based on Tesla Powerwall technology and includes a battery, inverter, and electrical panel.

8. Can the Tesla Tiny House run off-grid?

Absolutely. With the Energy Core and optional roof-mounted solar panels, it can operate fully off-grid.

9. How long does the battery last on a full charge?

Depending on energy usage, a 10–15 kWh battery can power essential functions for 12–48 hours without recharging.

10. How durable is the Tesla Tiny House?

The frame and shell are built with automotive-grade steel and aluminum, providing long-term durability and weather resistance.

11. Does the house go through safety testing?

Yes. Each unit undergoes:

- Rain chamber leak tests

- Vibration/transport tests

- Full electrical load testing

- Ventilation and airtightness checks

12. Can the tiny house be used as a rental or Airbnb?

Yes. It’s designed for immediate move-in, making it ideal for rentals, guest houses, or vacation properties.

13. Is a permit required to install a Tesla Tiny House?

Permit requirements vary by city and state. Many areas allow tiny homes as ADUs, but local zoning laws should be checked.

14. How many Tesla Tiny Houses can be built per year?

With only 5–10% of Tesla’s frame manufacturing capacity, the company could produce 90,000–180,000 units annually.

15. When will the Tesla Tiny House be available for purchase?

Tesla hasn’t officially announced a public release date yet, but production concepts and prototype details indicate it’s in active development.

Read More:

- What Rocket Lab Just Did to Catch up with SpaceX Just Changed Space Race Forever

- Tesla supplements Holiday Update by sneaking in new Full Self-Driving version

- Tesla hints at Starlink integration with recent patent

- IT HAPPENED! 2026 Tesla Pi Pad: FINALLY Available Now for Just $119

- NVIDIA Is Finished – Elon Musk’s First Tesla GPU Chip is Finally Here

- SpaceX Breaks Record with Starship B19 Stacking Completed in Weeks! How is this possible so fast?

Can you put modules together to form a larger living area?