The era of “driving for three hours and charging for two” is officially over. Tesla has completely redefined long-haul trucking with the Tesla Semi Gen 2, and it’s reshaping the logistics industry faster than anyone could have predicted. Based on data collected from Tesla Semi-D drivers over the past two years, a fully loaded Tesla Semi driven for approximately 7 hours requires only about 45 minutes to recharge its battery on average.

When Elon Musk stated that 2026 would be a breakout year for Tesla, many assumed he was referring to the Tesla Optimus robot or Robo Taxi. However, what few anticipated was that he was hinting at the Tesla Semi, a vehicle considered Tesla’s most ambitious and technically challenging project to date.

On the very first day of 2026, Musk unveiled the latest design of the Tesla Semi, the Gen 2 commercial version scheduled for release later this year. With upgrades including 1.2 megawatt charging infrastructure, drivers now have the confidence to transition rapidly from diesel-powered trucks to fully electric fleets.

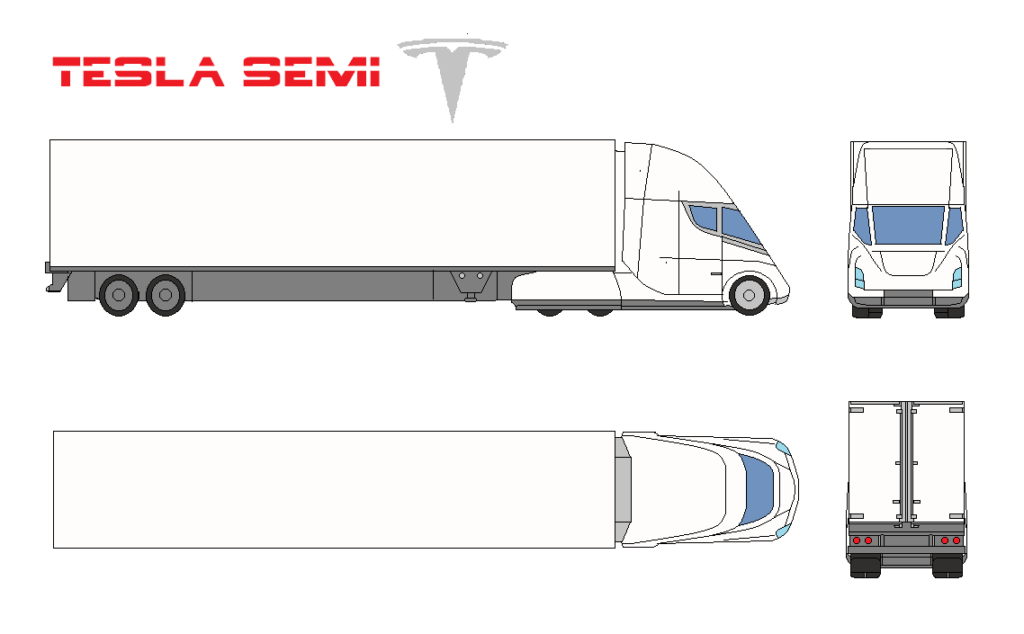

Tesla Semi Gen 2 Design Evolution: Beyond Cosmetic Refinement

At first glance, the Tesla Semi still maintains a familiar modern silhouette, pristine white bodywork, and a central driving position, signaling that this is no ordinary heavy-duty truck.

However, comparing the 2017 prototype with the latest Gen 2 design reveals a fundamental redesign focused on efficiency, manufacturability, serviceability, and autonomy.

Front-End and Aerodynamic Improvements

The most noticeable differences are at the front end. The 2017 Semi featured an aggressive, concept-car-like nose, steeply sloped windshield, and complex front bumper geometry designed for aerodynamic appeal rather than practical production.

By contrast, the Gen 2 Tesla Semi features:

- Cleaner, more streamlined front bumper divided into modular sections

- Simplified lighting bar design for improved visibility

- Lower repair complexity, translating to reduced downtime and insurance costs

These improvements reflect Tesla’s transition from experimental prototypes to mass-production vehicles built for daily operational efficiency.

Windshield, Roofline, and Drag Coefficient Upgrades

One heavily criticized aspect of the first-generation Tesla Semi was its oversized windshield and rear glass. While visually impressive, it added unnecessary weight, increased costs, and reduced thermal efficiency.

The Gen 2 redesign:

- Shortens the windshield and smooths the roofline

- Reduces drag coefficient from 0.36 to approximately 0.33

- Improves long-haul efficiency by 5-8%, equating to tens of extra miles per charge and thousands saved annually per truck

Even seemingly minor aerodynamic gains have major operational impacts for freight companies.

Transition to Mass Production

The first-generation Semi was effectively hand-built, with complex curves and heavy panels suitable for prototypes. Gen 2, however, is optimized for mass production, featuring:

- Flatter body panels and smoother transitions

- Cab structure designed for automated assembly

- Increased production targets of ~50,000 trucks per year (200 units per day)

This shift shows Tesla’s commitment to industrial scalability without sacrificing performance.

Weight Reduction and Payload Capacity

The curb weight of Gen 2 Tesla Semi is under 23,000 lbs, a major improvement over previous models.

Implications for fleet operators:

- Every pound saved in the tractor adds a pound of additional payload capacity

- Weight reduction directly translates to higher revenue per trip

- Revised chassis architecture distributes loads more evenly and reduces stress concentrations

This focus on weight optimization enhances both efficiency and durability for trucks expected to log millions of miles.

Tesla Semi Gen 2: Efficiency and Energy Consumption

The Gen 2 Semi has achieved energy consumption of 1.7 kWh per mile, representing approximately 15% more efficiency than the previous generation.

Contributing factors include:

- Aerodynamic improvements (roofline, panel transitions, airflow consistency)

- Advanced battery technology

- Optimized powertrain and software control

In real-world operations, these gains translate to substantial cost savings in electricity, operational efficiency, and reduced carbon emissions.

Headlights and Exterior Updates

The Gen 2 Semi features Model Y-inspired headlights with cleaner, more modern designs. Compared to the earlier generation:

- Smoother light bar design

- Slightly larger units to accommodate heavy-duty applications

- Improved visual appeal while maintaining high-performance illumination

Additionally, other exterior updates include:

- More compact side windows

- Silver diamond pattern anti-slip steps

- Subtle yet functional camera repositioning for self-driving readiness

Camera Placement and Autonomous Readiness

One of the most significant Gen 2 design evolutions is camera repositioning, particularly above the front wheel arches.

Benefits include:

- Enhanced redundancy and wheel tracking

- Low-angle visibility critical for full self-driving heavy-duty operations

- Reflects Tesla’s clear shift from experimental to production-ready autonomous trucks

Tesla is signaling that autonomy is no longer a question of if, but when.

Battery Technology and Payload Optimization

Tesla has transitioned the Semi to high-voltage 4680 battery cells, replacing the lower-energy LFP cells previously used in prototypes.

Advantages of 4680 cells:

- Energy density ~300 Wh/kg (vs. 175 Wh/kg for LFP)

- Lighter battery pack without sacrificing 500-mile range

- Higher payload capacity due to weight reduction

- Reduced total system cost and increased operational efficiency

This strategic choice allows Tesla to maintain range while improving payload capacity, efficiency, and production economics.

1.2 MW Ultra-Fast Charging

The Tesla Semi Gen 2 achieves an impressive 1.2 megawatt charging rate, a first for commercial EV trucks.

Key features:

- Redesigned, compact charging port aligned with Tesla’s NACS standard

- Integration with Mega Charger ecosystem

- Thermal and mechanical reliability for repeated high-power charging

Operational benefits:

- Recharge ~45 minutes during standard driver breaks

- Reduces downtime and increases fleet utilization

- Enables charging to coincide with mandatory rest periods

This upgrade represents a transformative step for electric long-haul trucking, allowing EV trucks to match diesel duty cycles.

Charging Infrastructure Standardization

Tesla’s move to a megawatt-compliant, MCS-standard connector ensures:

- Long-term compatibility with commercial EV charging networks

- Reduced risk of fleet operators being locked into proprietary solutions

- Flexible deployment for cross-regional logistics

Thermal management enhancements in the new port also minimize battery degradation and extend lifetime reliability.

Tesla Semi Gen 2 Interior and Driver Experience

While exterior design dominates attention, Tesla also made substantial interior improvements:

- Anti-slip steps for driver safety

- More ergonomic controls and updated dashboard

- High-tech platform designed for autonomous driving assistance

- Increased payload capacity without compromising comfort or usability

Every update emphasizes efficiency, safety, and commercial viability rather than merely visual appeal.

Production Readiness and Market Impact

The second-generation Tesla Semi is no longer an experimental vehicle. Tesla has moved beyond prototype testing to focus on mass production for real-world freight operations.

Market implications include:

- Higher fleet efficiency and lower operational costs

- Rapid transition from diesel to electric trucking

- Alignment with government incentives for sustainable transport

Tesla Semi Gen 2 is designed to win contracts, reduce downtime, and operate continuously, making it a game-changer for logistics and freight companies worldwide.

Strategic Takeaways

Key highlights of Tesla Semi Gen 2:

- 500-mile range with 1.2 MW charging

- 1.7 kWh per mile efficiency (~15% improvement)

- 4680 high-voltage battery pack for reduced weight and higher payload

- Advanced autonomous readiness with optimized camera placements

- Refined aerodynamic, manufacturable, and serviceable design

This is not just a redesign; it’s a strategic evolution aimed at industry dominance.

Conclusion: Tesla Semi Gen 2 – The Future of Freight

The Tesla Semi Gen 2 is poised to redefine commercial trucking, offering:

- Ultra-fast charging that aligns with driver schedules

- Increased payload efficiency and reduced operational costs

- Advanced autonomous driving readiness

- Aerodynamic and structural refinements for long-haul sustainability

Tesla has turned the Semi from a promise into a production-ready, mission-critical asset. For fleets and logistics companies, this vehicle represents a real alternative to diesel trucks, potentially reshaping the trucking industry in 2026 and beyond.

If 45-minute charging during a standard driver break becomes standard, the question remains: should governments accelerate regulations to phase out diesel trucks, or should the market naturally adopt this new technology?

Tesla Semi Gen 2 is not just an innovation—it’s a revolution in freight efficiency, sustainability, and industrial design.

FAQs

1. What is the Tesla Semi Gen 2?

The Tesla Semi Gen 2 is the latest electric heavy-duty truck from Tesla, designed for long-haul freight with improved aerodynamics, autonomous features, and 1.2 MW ultra-fast charging.

2. How far can the Tesla Semi Gen 2 travel on a single charge?

The Gen 2 Semi offers a 500-mile driving range per charge, optimized for long-haul trucking operations.

3. How fast can the Tesla Semi Gen 2 charge?

Thanks to its 1.2 megawatt charging capability, the Tesla Semi Gen 2 can recharge most of its battery in about 45 minutes, aligning with standard driver breaks.

4. What battery technology does Tesla Semi Gen 2 use?

Tesla Semi Gen 2 uses high-voltage 4680 battery cells, providing higher energy density, reduced weight, and increased payload capacity compared to previous LFP batteries.

5. How efficient is the Tesla Semi Gen 2?

The Semi consumes approximately 1.7 kWh per mile, which is around 15% more efficient than the previous generation, reducing operational costs for fleet operators.

6. What are the major design upgrades in the Tesla Semi Gen 2?

Key upgrades include:

- Streamlined front bumper and roofline

- Shortened windshield and optimized aerodynamics

- Compact side windows

- Camera repositioning for autonomous driving readiness

7. Is the Tesla Semi Gen 2 ready for autonomous driving?

Yes. Tesla has repositioned cameras and sensors to support full self-driving capabilities, making the Gen 2 Semi future-proof for autonomous operations.

8. How much weight has been reduced in the Tesla Semi Gen 2?

The Gen 2 Semi has a curb weight under 23,000 lbs, allowing more payload capacity and operational efficiency for fleet owners.

9. How does the Tesla Semi Gen 2 improve fleet productivity?

With ultra-fast charging, increased payload, and reduced downtime, the Tesla Semi Gen 2 significantly improves asset utilization and route efficiency.

10. When will Tesla Semi Gen 2 be available for purchase?

The Gen 2 Tesla Semi is scheduled for commercial release in 2026, with production ready to meet fleet-scale demands.

11. How does the 1.2 MW charging work?

The Tesla Semi Gen 2 integrates with Tesla’s Mega Charger network, allowing ultra-fast charging without compromising battery life or thermal stability.

12. What are the aerodynamic improvements in Tesla Semi Gen 2?

Tesla optimized the roofline, windshield, and body panels to reduce drag coefficient from 0.36 to 0.33, improving energy efficiency and range.

13. How does Tesla Semi Gen 2 compare to diesel trucks?

With 45-minute charging breaks, 500-mile range, and increased payload efficiency, the Gen 2 Semi can match or exceed diesel truck performance while eliminating emissions.

14. What are the key interior upgrades in Tesla Semi Gen 2?

Interior improvements include ergonomic controls, anti-slip steps, updated dashboard, and autonomous driving-ready platform, enhancing driver comfort and operational safety.

15. Will Tesla Semi Gen 2 reduce operational costs for fleets?

Yes. Through improved efficiency, faster charging, increased payload, and reduced maintenance, Tesla Semi Gen 2 can significantly lower operating costs compared to diesel trucks.

Read More:

- SpaceX’s Starship Transport Barge Finally Revealed and It is Not What You Think

- I subscribed to Tesla Full Self-Driving after four free months: here’s why

- Tesla price target boost from its biggest bear is 95% below its current level

- Tesla Giga Shanghai celebrates 5 million electric drive unit milestone

- Judge clears path for Elon Musk’s OpenAI lawsuit to go before a jury

- Tesla earns top honors at MotorTrend’s SDV Innovator Awards